Leave Your Message

When embarking on your next mechanical project, understanding the various types of Sprocket Bolts is essential for ensuring durability and reliability. Sprocket Bolts play a crucial role in securing essential components such as gears and sprockets, providing the necessary strength to withstand operational stresses. Choosing the right type of Sprocket Bolt can make a substantial difference in performance and longevity, ultimately influencing the success of your project.

In this guide, we will explore the top 10 Sprocket Bolt types you need to know. Each type has unique features and applications that cater to different requirements, making it vital to select the appropriate option based on your specific project needs. Whether you are working on a bicycle, motorcycle, or industrial machinery, this comprehensive overview will help you navigate the variety of Sprocket Bolts available. Understanding these differences not only enhances your craftsmanship but also ensures that your project stands the test of time.

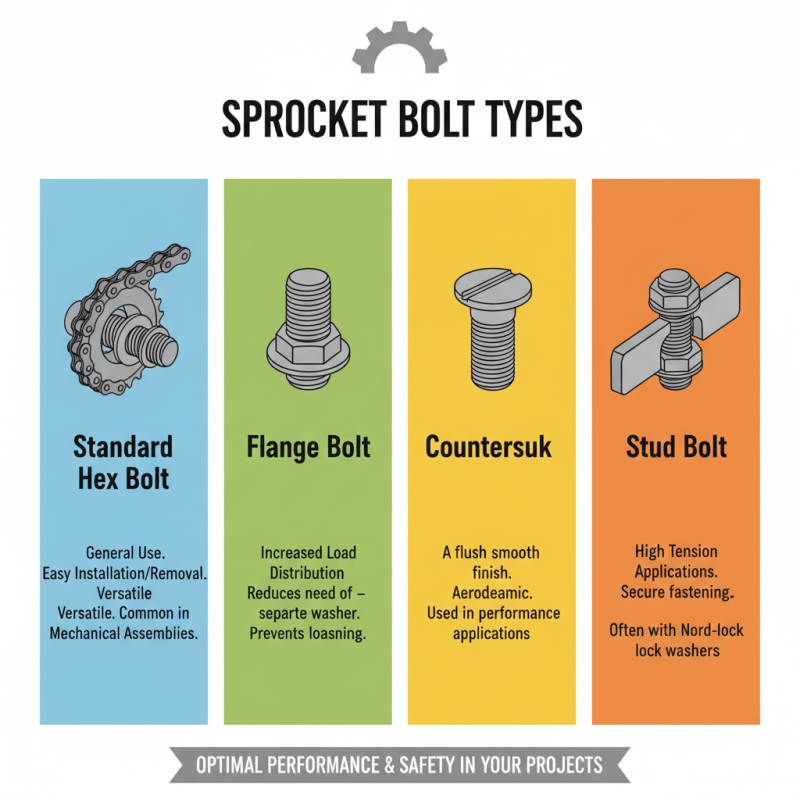

When it comes to selecting sprocket bolts for various applications, understanding the types available is crucial for achieving optimal performance and safety in your projects. There are several categories to consider, each serving distinct purposes. One common type is the standard hex bolt, which offers a straightforward design suited for general use. This type is favored for its ease of installation and removal, making it a preferred choice in many mechanical assemblies.

Another notable option is the shoulder bolt, which features a neck that provides a precise pivot point. This characteristic is particularly beneficial in applications requiring rotational movement, such as in conveyor systems or machinery with moving parts. Additionally, there are socket head bolts, recognized for their rounded heads and internal drive, allowing for access in tighter spaces. Variants such as locking and button head bolts also play significant roles, particularly when enhanced security or a lower profile is desired. By understanding these options, professionals can make informed decisions that enhance the reliability and durability of their projects.

When selecting sprocket bolts for your next project, understanding the common materials used in their construction is crucial. Sprocket bolts can be made from various materials, each offering distinct advantages tailored for specific applications. Steel, particularly carbon steel and stainless steel, is frequently chosen for its strength and durability. According to a report by the International Organization for Standardization (ISO), carbon steel bolts can withstand significant stress levels, making them ideal for high-load environments. Stainless steel, on the other hand, provides excellent corrosion resistance and is often preferred in marine and outdoor applications, ensuring longevity under harsh conditions.

Another material gaining popularity in industrial settings is titanium. Although it is more expensive, titanium bolts offer a high strength-to-weight ratio, making them ideal for lightweight applications such as in aerospace engineering. A data analysis from the Materials Research Society indicates that titanium bolts, while being about 45% lighter than stainless steel counterparts, maintain strength comparable to steel in extreme temperatures. Additionally, the use of aluminum alloys in sprocket bolts can significantly reduce weight while providing sufficient strength for less demanding tasks, appealing to industries focused on efficiency and fuel savings. Each material serves a unique purpose, so selecting the right one is vital to the success of any engineering project.

| Sprocket Bolt Type | Common Materials | Benefits |

|---|---|---|

| Hex Head Bolt | Steel, Stainless Steel | High strength, versatile |

| Socket Head Cap Screw | Alloy Steel, Carbon Steel | Compact design, high torque |

| Button Head Bolt | Aluminum, Stainless Steel | Aesthetic appeal, corrosion resistance |

| Flanged Bolt | Steel, Brass | Eliminates nut usage, even load distribution |

| Shoulder Bolt | Steel, Nylon | Pivot point, load bearing |

| Lag Screw | Steel, Zinc-plated | Heavy-duty, wood applications |

| Wing Bolt | Steel, Stainless Steel | Easy to tighten by hand, no tools needed |

| T-Bolt | Steel, Stainless Steel | Adjustable, locks in position |

| Eye Bolt | Steel, Forged Steel | Lifting and hoisting applications |

| Self-tapping Screw | Carbon Steel, Stainless Steel | Fast installation, no pre-drilling required |

When choosing the right sprocket bolts for your next project, several key features should be on your radar. First, consider the material of the bolt. Options range from stainless steel to high carbon steel, each offering different levels of strength, corrosion resistance, and durability. High carbon steel bolts typically provide superior strength, making them ideal for heavy-duty applications, while stainless steel is great for environments where rust and corrosion are concerns.

Another crucial feature is the bolt's head type and drive style. Whether you choose hex, socket, or another design, this can influence ease of installation and removal. Bolts with a larger head diameter may offer better torque capabilities but can also demand more space. Additionally, look into thread pitch and length; these factors must align with your specific sprocket requirements to ensure a secure fit. Ensuring you choose the right specifications will ultimately enhance the performance and longevity of your sprocket assembly.

Sprocket bolts are critical components across a variety of industries, providing the necessary connection and stability for rotating machinery. In the automotive sector, for example, sprocket bolts are integral to timing chain systems that synchronize engine movements, ultimately impacting vehicle performance and efficiency. According to a report from the Automotive Engineering Association, approximately 80% of modern vehicles utilize sprocket systems that rely on high-strength bolt designs to withstand tremendous forces and vibrations. This illustrates the dependence on highly durable materials to ensure safety and reliability in transportation.

In the manufacturing and industrial sectors, sprocket bolts play a vital role in conveyor systems and gear assemblies. A study published by the Industrial Processing Journal indicates that effective fastening solutions, including specific bolt types, can enhance operational efficiency by up to 25%. The study highlights that applications in heavy machinery, such as mining and construction equipment, require bolts made from robust alloys to manage stress and prevent failure under extreme conditions. Furthermore, aerospace applications are increasingly using specialized sprocket bolts due to their lightweight properties and strength, thereby contributing to reducing overall vehicle weight and improving fuel efficiency. Overall, the versatility of sprocket bolts ensures they remain a pivotal component in advancing technology across these industries.

When it comes to installing and maintaining sprocket bolts, adhering to best practices is crucial for ensuring the longevity and performance of machinery. According to a 2021 report by the Machinery Maintenance Institute, improper installation can lead to failures in 25% of mechanical systems, emphasizing the need for a precise approach. Proper torque specifications play a vital role in installation; using a calibrated torque wrench can significantly reduce the risk of premature wear or catastrophic failure. It is advisable to follow the manufacturer's guidelines regarding torque levels and installation sequence, as these are often determined based on extensive testing in various operating conditions.

Regular maintenance is equally important to prolong the lifespan of sprocket bolts. A study from the Engineering Mechanics Society notes that routine inspections can mitigate the risk of corrosion and fatigue, which are common contributors to bolt failure. Implementing a maintenance schedule that includes visual inspections and periodic replacements based on usage frequency can enhance operational reliability. Additionally, applying anti-seize compounds can prevent galling and make future disassembly much easier, thus contributing to sustained performance throughout the life of the equipment. Maintaining an organized record of inspections and repairs can also aid in identifying trends over time, ensuring that any potential issues are addressed before they escalate.