Leave Your Message

In the realm of automotive safety and performance, the significance of wheel bolts cannot be overstated. According to a recent report from the National Highway Traffic Safety Administration (NHTSA), improper installation and maintenance of wheel fasteners can lead to catastrophic vehicle failures, contributing to approximately 15% of all vehicle-related accidents. With vehicles becoming increasingly complex, the importance of understanding the various types of wheel bolts is paramount for every car owner.

Wheel bolts serve as critical components, ensuring the secure attachment of wheels to the vehicle's hub. Their role in maintaining proper alignment, stability, and overall safety is reflected in studies from the Society of Automotive Engineers (SAE), which indicate that over 30% of all vehicle maintenance issues can be traced back to neglect in wheel bolt upkeep. Understanding the different designs, materials, and specifications of wheel bolts not only enhances vehicle performance but also plays a crucial role in driver safety. As such, it’s essential for car owners to be informed about the top 10 wheel bolts that are vital to maintaining both vehicle integrity and road safety.

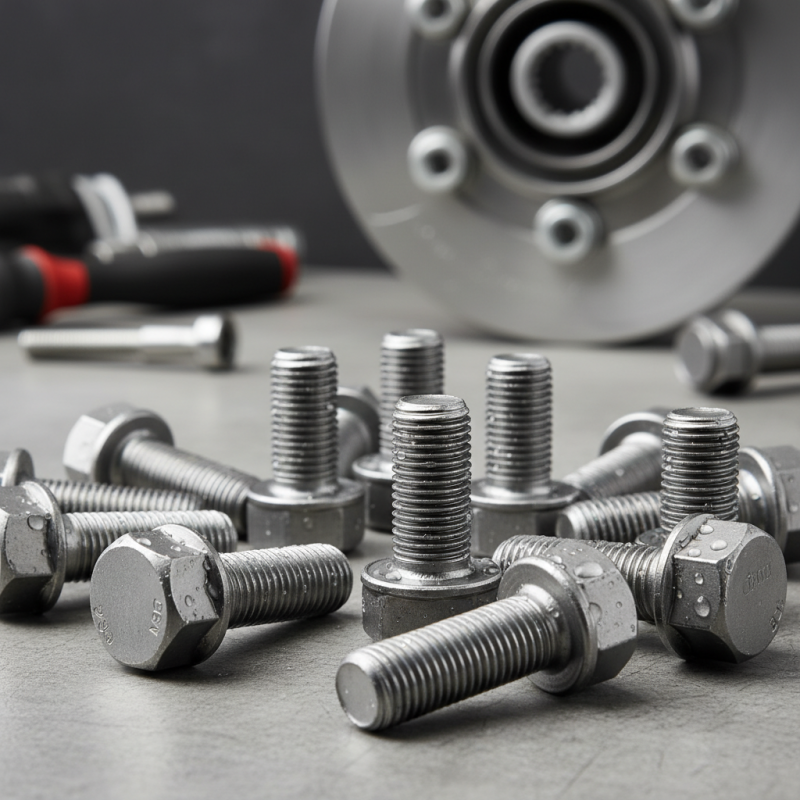

When it comes to vehicle safety, the often-overlooked component is none other than the wheel bolt. These small yet mighty fasteners hold the wheels securely to the hub, ensuring that everything runs smoothly and that the vehicle remains stable during operation. According to a report by the National Highway Traffic Safety Administration (NHTSA), over 2,500 accidents each year are attributed to improper wheel mounting, which often results from worn or damaged wheel bolts. This highlights the critical role that maintaining and understanding wheel bolts plays in overall vehicle safety.

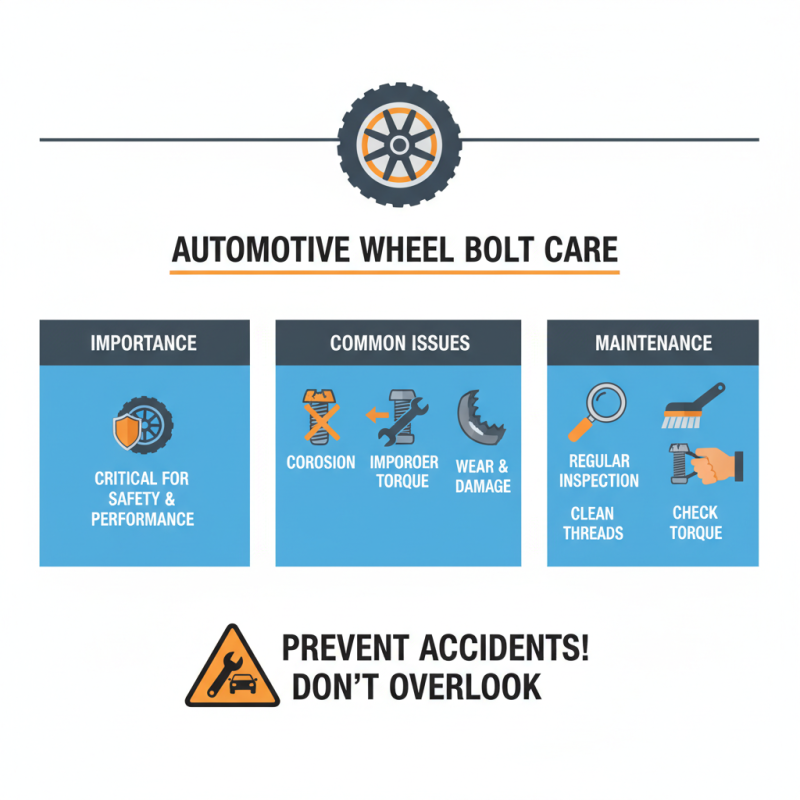

Regularly inspecting wheel bolts for signs of wear, corrosion, or damage can prevent potentially catastrophic situations. Tips for car owners include checking the torque specifications as recommended by the vehicle manufacturer, as improper torque can lead to stripped threads or wheel detachment. Additionally, it is advisable to replace wheel bolts at the first sign of wear and to ensure that the replacement bolts match the vehicle's specifications exactly.

Another essential tip is to familiarize yourself with the common types of wheel bolts, such as conical, flat, and spherical, each serving a specific purpose. Understanding the function and compatibility of these bolts can be crucial in maintaining vehicle integrity and safety. Moreover, investing in high-quality bolts can significantly reduce the risk of failure and enhance the durability of your vehicle's wheels. Prioritizing wheel bolt maintenance is an easy yet impactful way to ensure each journey is a safe one.

This chart shows the shear strength of various types of wheel bolts that every car owner should be aware of. Understanding the shear strength is crucial for vehicle safety, as it indicates the load a bolt can handle before failure. Proper selection of wheel bolts is essential for maintaining the integrity of your vehicle's wheels.

When it comes to vehicle maintenance, understanding the types of wheel bolts and their specific applications is crucial for every car owner. Wheel bolts are essential components that secure the wheels to the vehicle hub, and they come in various types tailored to different automobile makes and models. The most common types include conical, spherical, and flat seat bolts, each designed to provide optimal fit and security. For instance, conical seat bolts, often found on many passenger vehicles, are structured to fit snugly into the wheel's tapered hole, ensuring a tight connection that is vital for safe driving.

Moreover, the material composition of wheel bolts can vary significantly, affecting durability and performance. High-strength steel bolts are standard for most cars, providing excellent tensile strength. However, lighter vehicles may benefit from aluminum alloy bolts, which reduce weight while still offering adequate security. Additionally, certain performance vehicles may utilize titanium bolts for their lightweight properties and resistance to rust and corrosion. Regardless of the type and material, it’s important for car owners to choose the correct wheel bolts for their specific vehicles, as using incorrectly sized or incompatible bolts can lead to wheel misalignment or even accidents while driving. Understanding these distinctions empowers car owners to make informed decisions about their vehicle maintenance, ensuring both safety and performance on the road.

When choosing wheel bolts for your vehicle, it’s essential to focus on several key features to ensure safety and performance. First, check the bolt material. High-quality steel or aluminum is recommended for durability and strength, as these materials can withstand immense pressure and harsh conditions. Additionally, look for corrosion-resistant finishes that protect the bolts from rust and degradation over time, especially if you live in an area with heavy rain or snow.

Another crucial aspect to consider is the bolt size and thread pitch. Using incorrect sizes can lead to improper fitting, which undermines vehicle safety. Always refer to your car’s manual for specifications, and consider tools that can help you measure the existing bolts accurately.

**Tips:** Always ensure that the bolts are torqued to the manufacturer’s specified settings. An under-torqued bolt can come loose, while an over-torqued bolt might strip or break. Additionally, regularly inspecting your wheel bolts as part of your vehicle maintenance routine can help catch potential issues early on, preventing safety hazards down the line. When installing new wheel bolts, it's important to follow a star pattern for tightening to distribute pressure evenly across the wheel.

When it comes to automotive care, wheel bolts often go overlooked despite their critical role in vehicle safety and performance. Common issues that can arise with wheel bolts include corrosion, improper torque, and wear over time. Regular inspections can help car owners identify these problems early, preventing potential disasters such as wheel separation while driving. It's advisable to check for signs of rust or damage and to ensure that the threads are clean and free from debris.

Maintaining wheel bolts involves a few simple yet effective practices. Firstly, ensuring that they are tightened to the manufacturer's specified torque is crucial. This can be done using a torque wrench, which guarantees an even distribution of pressure across the wheel assembly. Additionally, applying a suitable anti-seize compound can help prevent corrosion, especially in regions where winter salt is prevalent. Washing the wheel area regularly can also minimize the accumulation of dirt and grime, which can lead to bolted connections failing over time. Through these preventive measures, car owners can enhance the longevity and performance of their wheel bolts, contributing to overall vehicle safety.

When it comes to vehicle maintenance, paying attention to your wheel bolts is crucial for ensuring both safety and performance. Several signs indicate it may be time to replace these essential components. One of the most noticeable signs is visible corrosion or rust on the bolts. Corrosion can weaken the structural integrity of the bolts, leading to potential failures while driving. If you notice any signs of deterioration on your wheel bolts, it’s wise to replace them promptly.

Another indicator that your wheel bolts may need replacement is if you experience vibrations or instability while driving. Unusual feedback from the steering wheel, particularly when navigating turns or during acceleration, can suggest that the bolts are no longer securely fastening the wheels. Additionally, if you find that some bolts are unusually loose after routine checks, this can also be a red flag. Over time, bolts can elongate and lose their grip, making it essential to keep an eye on their condition to maintain vehicle safety. Regular inspections and timely replacements can save you from the risks associated with wheel failures.