Leave Your Message

In the world of automotive performance, the importance of high-quality lug bolts cannot be understated. These essential components play a critical role in ensuring the proper attachment of wheels to a vehicle, directly affecting not only safety but also overall driving dynamics. As renowned automotive engineer Dr. Emily Hart states, “The right lug bolts can significantly enhance a vehicle’s stability and performance, making them a crucial investment for any serious car enthusiast.”

As we approach 2025, the market for lug bolts has experienced a revolution, with advancements in materials and engineering leading to improved performance and durability. This article explores the top 10 lug bolts that can elevate your vehicle’s capabilities in the coming years. With cutting-edge designs and innovative technology, these lug bolts promise not just enhanced safety but also an upgraded driving experience.

Join us as we delve into the top contenders, highlighting their features and benefits, and explaining why investing in top-tier lug bolts is essential for optimizing vehicle performance. Whether you are a daily driver or a motorsport enthusiast, understanding the impact of lug bolts is key to achieving your performance goals.

When selecting the appropriate lug bolts for your vehicle, understanding your vehicle’s specifications is paramount. Utilizing the correct size, thread pitch, and length not only ensures the safe attachment of wheels but also enhances overall vehicle performance. According to a report from the Tire Industry Association, improperly fitted lug bolts can lead to uneven wear on tires and suspension systems, potentially reducing the lifespan of these components by nearly 25%.

Different vehicles have varying requirements, influenced by factors such as weight, tire size, and intended use. For instance, a heavy-duty truck may require high-tensile-strength bolts that can withstand greater forces. The Society of Automotive Engineers indicates that using the appropriate grade of lug bolts can significantly impact a vehicle's handling and braking capabilities. When upgrading or replacing lug bolts, it's essential to consult your vehicle's manual or a professional to ensure compatibility with the OEM specifications, which often specify a minimum torque value to avoid wheel detachment incidents.

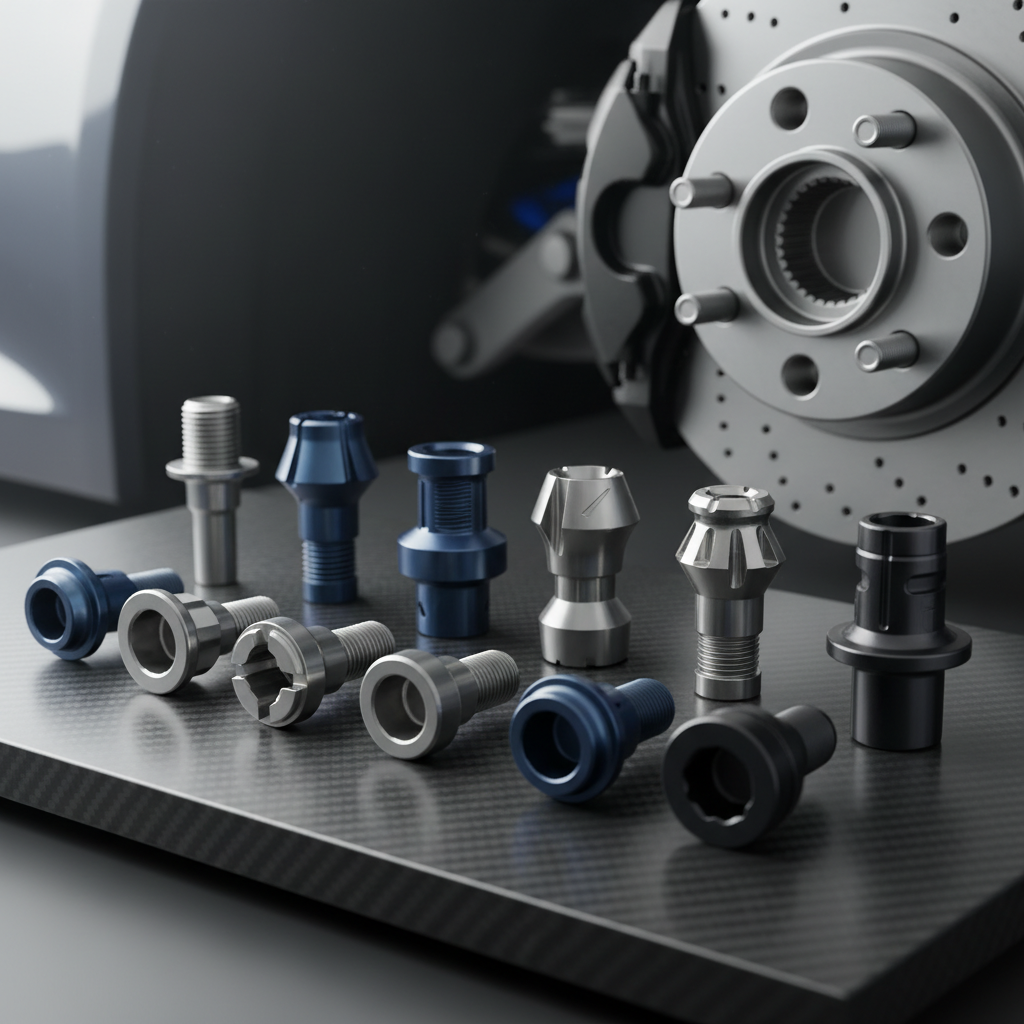

When it comes to enhancing vehicle performance, the materials used in lug bolts play a crucial role. High-quality lug bolts are designed not only for durability but also to handle extreme conditions, including the high-speed demands of motorsports. For instance, lightweight materials such as titanium and advanced alloys are favored in racing applications due to their strength-to-weight ratio, contributing to quicker pit stops and improved handling dynamics. Reports indicate that using premium lug bolts can reduce unsprung weight by an average of 10-15%, significantly impacting overall vehicle performance.

Tip: When selecting lug bolts, consider those made from aerospace-grade materials, as they offer superior strength and resistance to corrosion. It’s also essential to match the lug bolt specifications with your vehicle’s requirements to prevent any premature wear or failures.

In addition, aftermarket wheels can further optimize performance. Investing in wheels designed for your specific model parameters can enhance both aesthetic appeal and handling. A recent analysis found that proper wheel selection can improve traction by up to 20%, making it essential for any vehicle enthusiast aiming for the best performance.

Tip: Always pair your wheel upgrade with compatible lug bolts, as mismatched components can lead to dangerous handling issues.

This chart demonstrates the impact of various lug bolt materials on the performance characteristics of vehicles. It highlights the tensile strength and weight of each material, indicating their effectiveness in enhancing vehicle performance.

When selecting lug bolts to enhance vehicle performance, several essential features should be prioritized.

Firstly, the material quality of the lug bolts plays a significant role in their durability and resilience.

According to a report by the Society of Automotive Engineers, high-grade steel or alloy materials used in lug bolts can significantly improve load-bearing capacity and tensile strength.

This is critical, as the lug bolts need to withstand the dynamic forces encountered during driving, particularly in high-performance or heavy-duty vehicles.

Another important aspect is the bolt thread design and sizing. Research from the International Journal of Automotive Engineering emphasizes that proper thread engagement and pitch can reduce the chances of striping, allowing for optimal clamping force.

Furthermore, the performance of lug bolts can be enhanced by features such as corrosion resistance, often achieved through proper coating techniques like zinc plating or chrome finishing.

These coatings not only extend the life of lug bolts but also prevent loosening over time, ensuring safety and reliability, especially in challenging driving conditions.

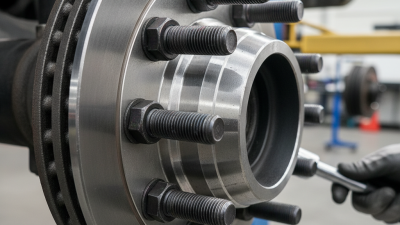

When it comes to enhancing vehicle performance, the installation of lug bolts plays a crucial role in ensuring safety and stability. To achieve optimal performance, it is essential to start with the right tools. Using a torque wrench will allow you to apply the correct amount of torque to your lug bolts, preventing under-tightening or over-tightening, both of which can lead to wheel detachment or brake system failure. Always adhere to the vehicle manufacturer's specifications for torque settings to maintain the integrity of your wheels.

Additionally, it's vital to inspect the lug bolts before installation. Check for signs of wear, rust, or damage, as compromised lug bolts can negatively affect vehicle performance and safety. Cleaning the bolt threads and the wheel hub surface can also improve the contact between the bolt and the wheel. Applying a light coating of anti-seize lubricant can help mitigate galling and make future removals easier.

By carefully following these installation tips, you can ensure that your lug bolts provide the enhanced performance and reliability you need for a safe driving experience.

Maintaining lug bolts is crucial for ensuring the safety and performance of your vehicle. Regular inspection and maintenance can help prolong their lifespan and prevent issues such as loosening and corrosion. Start by checking the torque of your lug bolts periodically, especially after tire rotations or replacements. Using a torque wrench ensures that they are tightened to the manufacturer’s specifications, preventing excessive wear and potential failure.

Tips for maintaining lug bolts include keeping them clean and free from rust. Dirt and grime can accumulate over time, leading to difficulties when removing the bolts. Additionally, applying a small amount of anti-seize compound on the threads can help reduce friction during installation and removal, making it easier and safer to work with your lug bolts. Be mindful of environmental factors as well; exposure to moisture and road salt can accelerate rust formation, so consider inspecting your bolts after harsh weather conditions.

Lastly, when replacing tires, pay attention to the condition of your lug bolts. If you notice any signs of wear, such as cracks or significant rust, it's wise to replace them immediately to ensure safe operation. Regular maintenance not only enhances vehicle performance but also promotes a reliable driving experience.