Leave Your Message

When it comes to maintaining optimal performance in vehicles, understanding the mechanics of the suspension system is crucial. One of the key components within this system is the Center Bolt Leaf Spring. This element plays a vital role in supporting the vehicle's weight, ensuring a smooth ride, and contributing to overall stability. Over time, however, these leaf springs may experience wear and tear, necessitating replacement and proper maintenance to uphold the vehicle's performance.

Replacing the Center Bolt Leaf Spring is a task that requires careful attention and knowledge of the suspension mechanisms. If executed correctly, it can enhance the vehicle's handling, improve load distribution, and extend the lifespan of the suspension system. In this guide, we will explore the essential steps for replacing and maintaining the Center Bolt Leaf Spring, as well as the indicators that signal when a replacement is needed. By understanding these fundamentals, vehicle owners can ensure their suspension system operates efficiently, providing a safer and more comfortable driving experience.

The center bolt leaf spring plays a crucial role in vehicle suspension systems, primarily by providing

support and absorbing shocks from the road. This type of spring, usually found in trucks and heavy-duty vehicles, is designed to carry loads

effectively while maintaining stability. When a vehicle encounters bumps or uneven surfaces, the leaf spring flexes to cushion the impact,

ensuring a smooth ride for passengers and cargo alike. The center bolt serves as a pivotal point, allowing the leaf springs to act collectively,

distributing weight and mitigating stress on the vehicle's frame.

Understanding the function of the center bolt leaf spring is essential for maintaining optimal vehicle performance.

By securing the individual leafs together, the center bolt enhances the spring's

tensile strength and resilience. This mechanism not only enables the spring to flex under load

but also contributes to the overall integrity of the suspension system. Regular inspections and maintenance of the center bolt and surrounding

components can prevent wear and ensure that the vehicle maintains proper ride height and handling characteristics. Properly functioning

leaf springs, with an intact center bolt, are vital for achieving stability, safety, and efficiency in any vehicle’s suspension setup.

Recognizing the signs of wear and tear in leaf springs is crucial for maintaining vehicle safety and performance. Leaf springs play a vital role in a vehicle's suspension system, responsible for supporting the weight of the vehicle and absorbing shocks from the road. According to industry data from the National Highway Traffic Safety Administration, improper maintenance of suspension components can lead to compromised vehicle handling and increased risk of accidents. Regular inspections are essential for detecting issues early on.

Common indicators of wear in leaf springs include sagging, cracking, or breaking. If a vehicle appears to be leaning to one side or if there is a noticeable decrease in ride height, these may be signs that the leaf springs need replacement. Additionally, unusual noises such as creaking or squeaking while driving may indicate that the springs are not functioning effectively. Experts recommend inspecting leaf springs at least once a year or more frequently if the vehicle is used heavily for towing or off-road activities.

**Tips for Maintenance:**

- Regularly check the leaf springs for visible signs of damage, such as rust or deformation, particularly after harsh weather or rough road conditions.

- Ensure that all brackets and mounting hardware are secure, as a loose component can lead to accelerated wear.

- Consider using shock absorbers that are matched to your leaf spring setup to improve the overall suspension performance and extend the lifespan of your leaf springs.

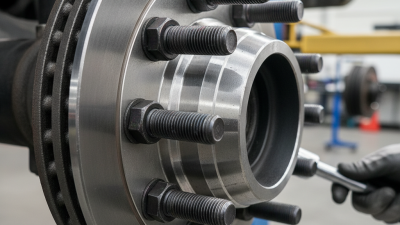

Replacing the center bolt leaf spring components is crucial for maintaining optimal performance in your vehicle's suspension system. Start by safely lifting the vehicle and securely supporting it with jack stands. Remove the wheel and inspect the leaf springs for any signs of wear or damage. Once you have isolated the center bolt area, use appropriate tools to remove the old bolt, being cautious of any remaining tension in the springs. Make sure to clean the mounting surfaces thoroughly before installing the new components.

After preparing the area, position the new center bolt and tighten it according to the manufacturer's specifications. This ensures that the springs remain properly aligned and function efficiently. It is also advisable to lubricate the leaf springs to reduce friction and prolong their lifespan. Pay attention to the proper reassembly of all components and ensure they are securely fastened.

**Tips:** Always wear safety gear, including gloves and goggles, when performing maintenance on your vehicle. Regular inspection of your leaf springs can preemptively identify issues before they require extensive repairs. Additionally, consider consulting a professional if you are uncertain about any steps in the replacement process to ensure safe and effective work.

| Step | Task | Tools Required | Safety Precautions |

|---|---|---|---|

| 1 | Lift the vehicle | Jack, jack stands | Ensure the vehicle is stable |

| 2 | Remove the wheel | Lug wrench | Wear safety glasses |

| 3 | Disconnect the leaf spring | Wrench set | Use gloves to protect hands |

| 4 | Replace the center bolt | New center bolt, socket set | Follow torque specifications |

| 5 | Reassemble the leaf spring | Wrench, torque wrench | Double-check connections |

| 6 | Reattach the wheel | Lug wrench | Ensure lug nuts are tight |

| 7 | Lower the vehicle | Jack | Remove jack stands cautiously |

| 8 | Test drive | N/A | Listen for unusual noises |

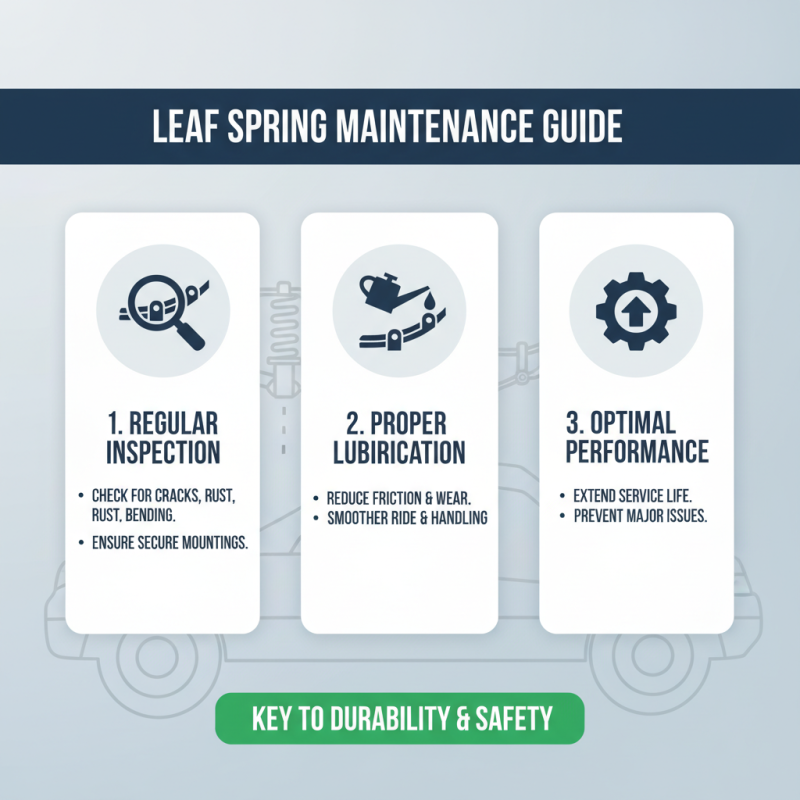

Maintaining leaf springs is crucial for ensuring optimal performance and extending their service life. Regular inspections can help detect any signs of wear or damage before they escalate into more significant issues. Check for cracks, rust, or any bending in the springs, and ensure that the mountings are secure. Proper lubrication of the leaf springs can also reduce friction and wear, facilitating a smoother ride and improving handling.

Tips: Always follow the manufacturer’s guidelines for maintenance intervals, and consider applying a protective coating to prevent corrosion. Keeping the leaf springs clean from dirt and debris is essential, as accumulated grime can lead to premature rusting and deterioration.

In addition to inspections and cleaning, it’s beneficial to maintain the correct load on your leaf springs. Overloading can significantly reduce their lifespan and performance. If you plan to carry heavy loads consistently, consider modifying your setup to accommodate these changes. Furthermore, rotating the leaf springs periodically can help distribute wear more evenly across the springs, enhancing their longevity and reliability.

Leaf springs are essential components in many vehicles, providing crucial support and stability. Regular inspection and maintenance are vital to ensure their optimal performance. According to industry standards outlined in the Automotive Research Journal, leaf springs should be inspected every 10,000 to 15,000 miles, or at least annually for heavy-duty applications. Key indicators of wear include the presence of cracks, rust, or sagging. Proper maintenance can extend the lifespan of leaf springs significantly, as neglected springs may lead to uneven tire wear and compromised vehicle handling.

Tips for maintaining leaf springs include regularly cleaning the springs to remove dirt and grime, which can cause corrosion. Apply a protective coating to prevent rust formation, especially in areas prone to moisture. Furthermore, ensure that the bolts and bushings are checked for tightness and signs of wear; loose components may lead to excessive movement and potential spring failure.

Additionally, following the guidelines set by the International Society of Automotive Engineers (SAE), ensure that leaf springs are visually inspected for any deformation or damage during regular maintenance checks. Using specialized tools like a caliper or measuring tape can help in assessing any changes in leaf spring symmetry and height over time. Keeping informed about the latest testing methods and maintenance practices can facilitate better decision-making in maintaining leaf springs effectively.