Leave Your Message

The suspension system of a vehicle plays a crucial role in delivering a smooth ride, maintaining control, and ensuring the safety of passengers. Among the various components that contribute to effective suspension, the Center Bolt Leaf Spring stands out for its significance in supporting the vehicle's weight and absorbing shocks from the road. A study published by the Automotive Engineering Institute in 2022 highlights that approximately 40% of suspension-related issues in vehicles stem from wear and tear of leaf springs, indicating their vital role in vehicle performance.

Replacing a worn or damaged Center Bolt Leaf Spring can lead to substantial improvements in handling, comfort, and load-bearing capacity. According to recent reports, vehicles equipped with properly maintained leaf spring systems show a 20% reduction in overall ride harshness. This underscores the necessity of regular inspections and timely replacements of the leaf spring components, particularly the center bolt that holds the assembly together. As vehicle manufacturers continue to innovate within suspension technology, understanding how to replace the Center Bolt Leaf Spring effectively becomes essential for both safety and longevity in suspension performance.

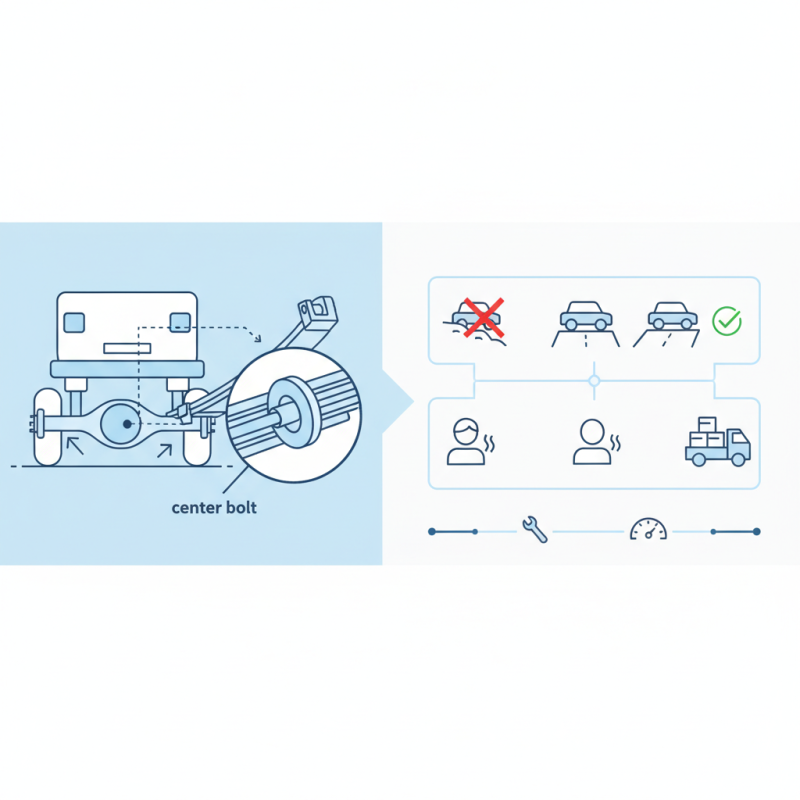

Center bolt leaf springs play a crucial role in the overall performance and safety of a vehicle's suspension system. These components are typically found in heavier vehicles, such as trucks and SUVs, and serve to support the vehicle's weight while absorbing shocks from the road. The center bolt acts as a pivot point for the leaf spring, allowing it to flex and provide the necessary support. This flexibility not only enhances ride comfort but also maintains stability when cornering or traversing uneven terrain.

Understanding how center bolt leaf springs function helps in recognizing the importance of their maintenance and potential replacement. Over time, these components can experience wear due to repeated stress and fatigue, resulting in diminished performance and compromised safety. A weakened center bolt can lead to misalignment of the leaf spring, causing uneven tire wear and instability. Therefore, when replacing a center bolt, it is essential to ensure proper installation to restore the leaf spring's function. This ultimately leads to improved handling and a safer driving experience, making it vital for vehicle owners to pay attention to this aspect of their suspension system.

When it comes to vehicle suspension, the center bolt leaf spring plays a crucial role in ensuring a smooth ride and maintaining stability. Over time, these components can become worn or damaged, leading to several noticeable symptoms that indicate their need for replacement. Drivers may experience excessive bouncing, difficulty in steering, or an uneven ride height, all of which can compromise the overall safety and handling of the vehicle. Unusual noises during motion, such as creaking or clunking, can also suggest that the leaf springs are struggling and require attention.

To help identify whether your center bolt leaf springs are in distress, pay attention to the ride quality. If you notice your vehicle swaying more than usual while turning or if the rear of your vehicle seems to sag, these are clear signs that the springs may be losing their effectiveness. Additionally, inspect the springs for any visible signs of cracks or rust, which often indicate that they are nearing the end of their lifespan.

Tips for maintaining leaf spring integrity include regularly inspecting your vehicle’s suspension components and ensuring that the bolts are properly torqued. Also, consider scheduling a routine alignment check, as improper angles can put extra strain on leaf springs, leading to premature wear. Addressing minor issues early can help extend the life of your suspension system and improve your overall driving experience.

| Symptoms | Causes | Visual Inspection | Replacement Steps |

|---|---|---|---|

| Uneven tire wear | Worn center bolt or leaf springs | Check for cracks or deformation | Lift vehicle, remove old springs, and install new ones |

| Bumpy ride | Damaged leaf springs | Inspect for rust and breaks | Unbolt leaf springs and replace center bolt |

| Vehicle sagging | Broken center bolt | Look for misalignment | Position vehicle, replace worn components |

| Noisy suspension | Loose or deteriorated components | Identify any loose parts | Tighten or replace faulty leaf springs |

When it comes to enhancing your vehicle's suspension, replacing the center bolt leaf springs can make a significant difference. To begin this process, ensure you have the necessary tools, including a jack, jack stands, and a wrench set. First, securely raise the vehicle and locate the leaf spring assembly. Before proceeding, it’s vital to relieve any tension in the springs. This can be accomplished by carefully loosening the U-bolts that hold the leaf springs in place. Once tension is released, remove the U-bolts completely and detach the leaf springs from the axle.

With the old leaf springs out, take the opportunity to inspect related components for wear or damage. Position the new leaf springs in place and align them properly with the axle. Replace the center bolt if necessary, ensuring it is securely fastened. Reinstall the U-bolts, again tightening them evenly to distribute pressure across the leaf springs. Finally, lower the vehicle and double-check all connections to confirm they are secure. This process not only improves suspension performance but also enhances overall safety while driving.

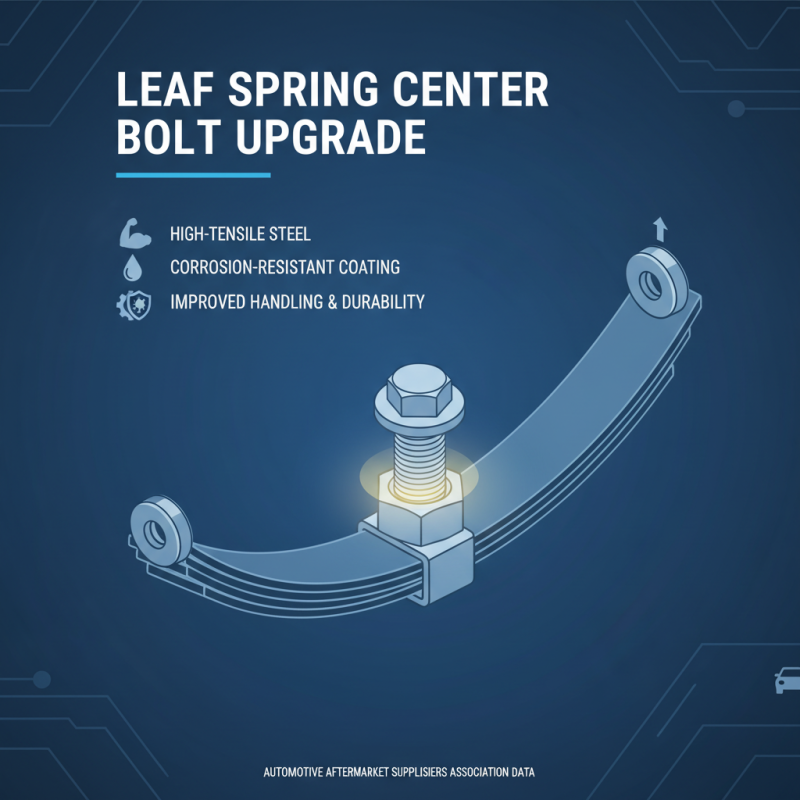

When replacing the center bolt of a leaf spring in your vehicle’s suspension system, selecting the correct replacement parts is crucial for optimal performance. The material and specifications of the parts can significantly impact the vehicle's handling and durability. For instance, data from the Automotive Aftermarket Suppliers Association highlights that using high tensile strength steel can reduce the risk of failure under heavy loads, providing added stability during operation. It’s also essential to consider the coating on these parts; corrosion-resistant coatings can extend the lifespan of the components, ensuring they withstand various environmental conditions.

One key aspect to consider is the specification of the leaf springs themselves. According to a report from the International Truck and Engine Corporation, the thickness and arch of the leaf springs are critical factors that influence the spring's load capacity and ride quality. Ensuring the replacement part meets or exceeds the original equipment specifications can help maintain vehicle integrity and performance.

Tips: When sourcing replacement parts, always consult your vehicle’s manufacturer guidelines to ensure compatibility. Additionally, investing in high-quality, OEM-equivalent parts can be a worthwhile consideration for longevity and safety. Regular inspections of the suspension system can also help identify potential issues before they develop into more severe problems.

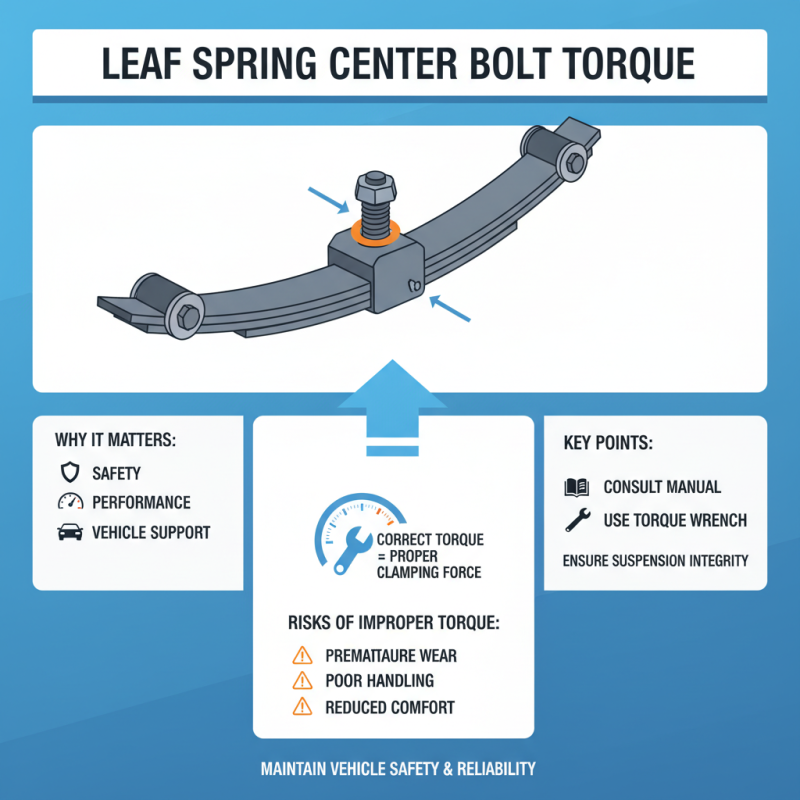

When replacing the center bolt leaf spring, achieving the correct torque settings is essential for ensuring the safety and performance of a vehicle's suspension system. Leaf springs play a crucial role in supporting the vehicle's weight and absorbing shocks from the road. Improper torque can lead to inadequate clamping force, resulting in a suspension that does not operate as intended. This can cause premature wear, compromising handling and comfort.

Applying the specified torque settings ensures that the leaf spring components are securely fastened, reducing the likelihood of movement or separation during operation. Over-tightening can lead to material fatigue or damage, while under-tightening may result in a loss of stability or even failure of the spring. It is vital to utilize a calibrated torque wrench for accuracy and to follow the manufacturer's guidelines for the appropriate torque specifications. This attention to detail helps maintain structural integrity and prolongs the lifespan of the suspension system, ultimately contributing to a safer driving experience.