Leave Your Message

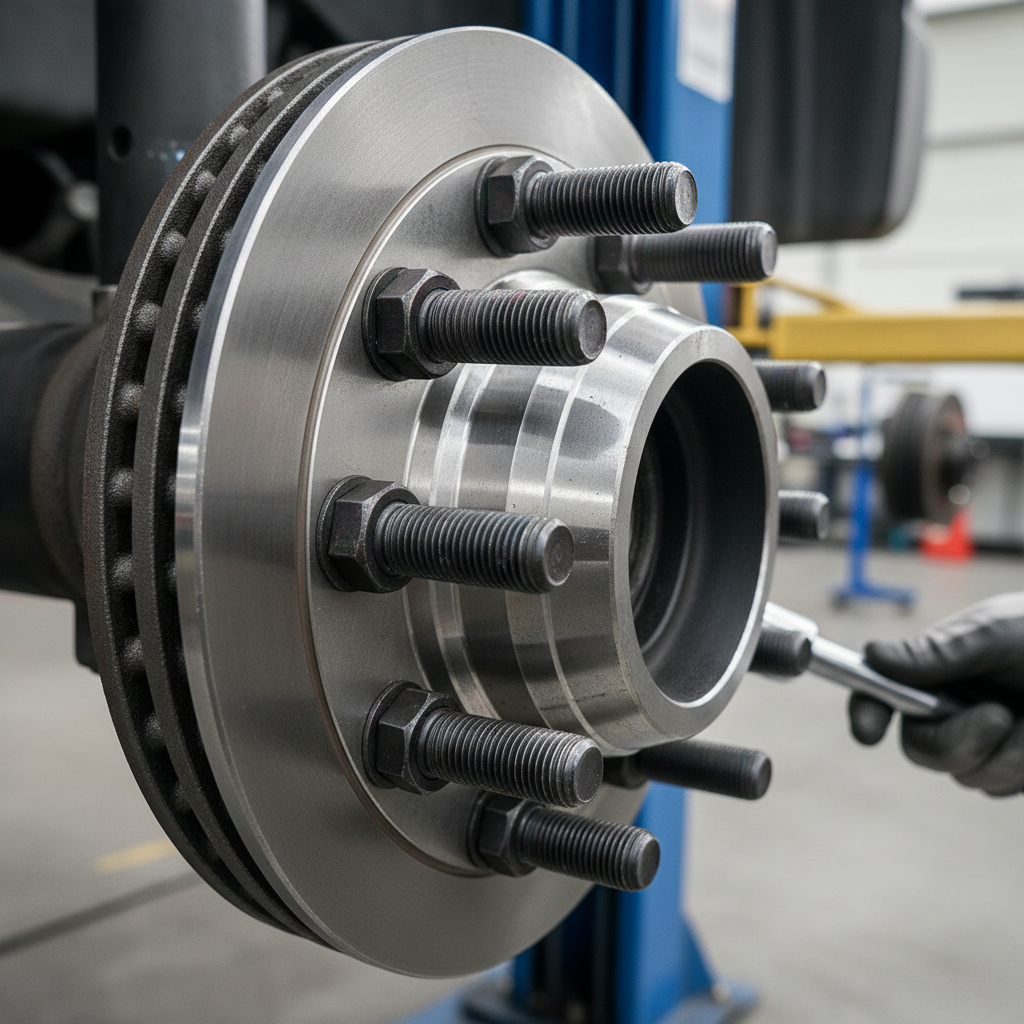

In the realm of automotive engineering, the significance of quality axle bolts cannot be overstated, especially in 2023 as vehicles become increasingly sophisticated. Axle bolts, serving as critical fasteners in the suspension and drivetrain systems, bear the brunt of stresses from various driving conditions. According to the National Highway Traffic Safety Administration (NHTSA), improper maintenance and inferior component quality are leading contributors to vehicle failures, with over 30,000 crashes annually attributed to defective parts. Ensuring that axle bolts meet stringent manufacturing standards is thus paramount for enhancing both safety and vehicle performance.

Recent reports from the Automotive Aftermarket Industry Association (AAIA) indicate that the global automotive fastener market is projected to reach $20 billion by 2026, underscoring the growing demand for high-quality components. The emphasis on durability and resilience in axle bolts not only improves operational efficiency but also reduces the risks associated with vehicular malfunctions. As we look to the future, selecting the right axle bolts can ultimately mean the difference between reliable performance and catastrophic failure, making them an indispensable element of vehicle safety and integrity.

Axle bolts are integral not just to vehicle assembly but to the broader framework of automotive design and engineering. These components play a crucial role in ensuring the safety and performance of modern vehicles. In 2023, advancements in driveline technology emphasize the need for high-quality axle bolts, which serve as the vital connections in a vehicle's powertrain. As the automotive industry pushes for higher performance and safety standards, the importance of these components cannot be overstated.

Recent industry reports indicate that approximately 30% of vehicle recalls are linked to driveline component failures, underscoring the necessity for reliable axle bolts. With electric vehicles becoming more mainstream, manufacturers are increasingly investing in innovative materials and designs to enhance the durability of axle bolts. Engineers are now exploring high-strength alloys and advanced coatings to improve resistance to wear and fatigue. Given the critical role that these bolts play in distributing loads and maintaining chassis integrity, the quality of axle bolts directly affects not only vehicle performance but also passenger safety. As seen in the recent feedback from drivers regarding failures of known defective parts, ensuring the reliability of every component, including axle bolts, is essential for maintaining consumer trust and operational efficiency in the evolving automotive landscape.

This chart illustrates the critical role of quality axle bolts in various aspects of vehicle safety and performance, highlighting their significance in modern vehicle design and engineering.

In 2023, the importance of quality axle bolts cannot be underestimated when it comes to overall vehicle safety and performance. These seemingly minor components play a critical role in determining a vehicle's load-bearing capacity, directly influencing its handling and stability. High-quality axle bolts are designed to withstand significant stress and force, ensuring that they do not fail under heavy loads or during demanding driving conditions. As a result, vehicles equipped with reliable axle bolts tend to achieve higher safety ratings, making them a smarter choice for both manufacturers and consumers.

When selecting axle bolts, it's essential to consider their material and design. Opt for bolts made from high-strength steel or other durable materials, as these are more resistant to wear and corrosion. Additionally, ensure the bolts are designed to meet or exceed industry standards for load capacity. Regular inspections and maintenance can also help identify any signs of wear or damage before they become serious issues.

**Tips:** Always replace axle bolts in pairs to maintain even force distribution. Keep a close eye on your vehicle’s handling characteristics; any unusual vibrations or noises might indicate compromised axle bolts. Finally, consult a professional mechanic to assess the quality of your axle bolts, especially if your vehicle frequently carries heavy loads.

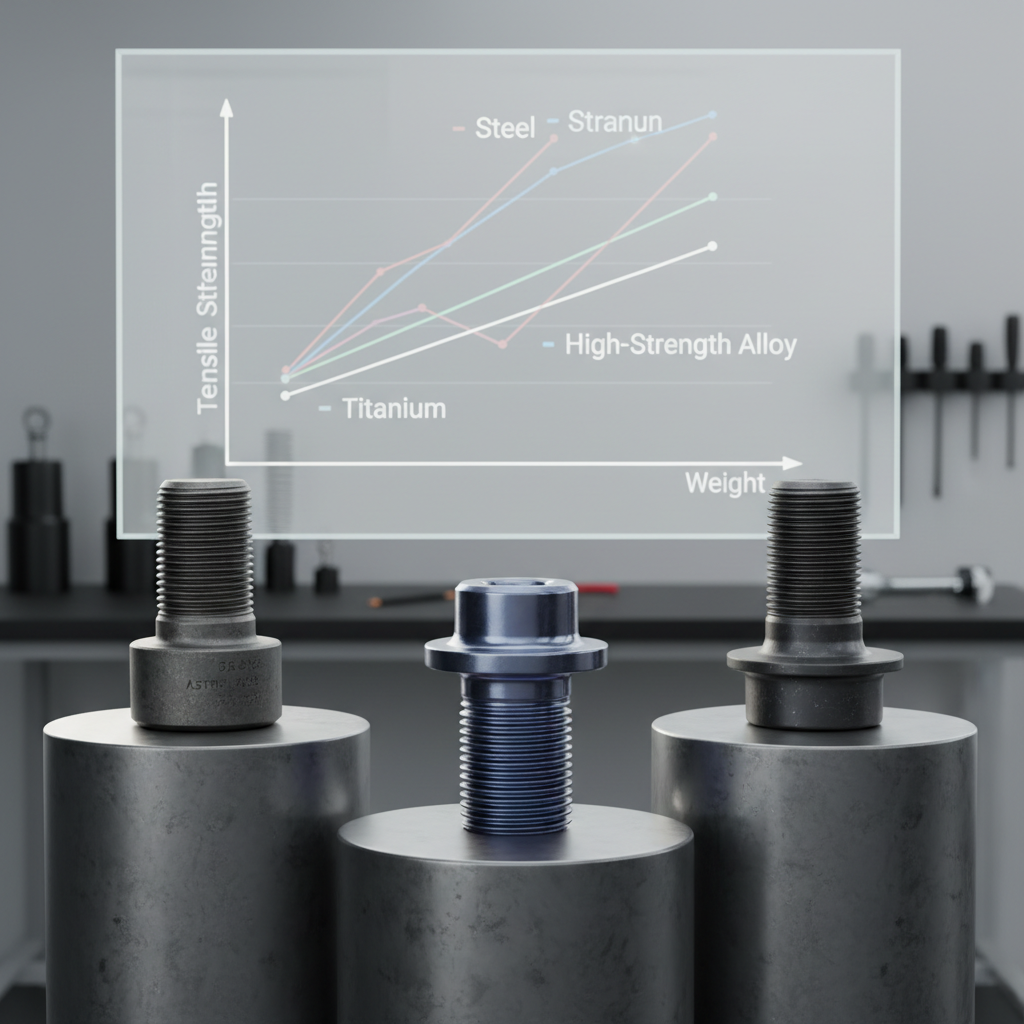

When it comes to vehicle safety and performance, the quality of axle bolts cannot be overstated. A comparative analysis of different materials used in axle bolt manufacturing reveals significant implications for durability and reliability. Steel is the most common material due to its balance of strength and cost-effectiveness, often meeting industry standards like SAE J429 and ASTM A325. However, advancements in materials such as titanium and high-strength alloys are making waves in the industry. Titanium, while more expensive, offers an incredibly high strength-to-weight ratio, making it ideal for performance vehicles where weight savings are crucial.

Additionally, recent studies highlight that carbon steel bolts, when properly heat-treated, can achieve tensile strengths exceeding 180,000 psi, significantly improving their resistance to shear and fatigue failures. This is essential, considering that a significant portion of axle bolt failures—estimated at 20% in some reports—are attributed to material deficiencies or improper installation. Thus, choosing the right material for axle bolts can greatly enhance vehicle safety.

Tips: When selecting axle bolts, always prioritize those that meet or exceed relevant industry standards. Regular inspections and maintenance can help prevent premature wear and failure, ensuring your vehicle remains safe and performs optimally. Additionally, consider consulting a vehicle specialist to ensure that the material selected aligns with your vehicle's specific needs and usage conditions.

In 2023, ensuring vehicle safety and performance heavily relies on the quality of axle bolts. Industry standards and testing protocols play a critical role in determining the durability and performance of these crucial components. Manufacturers today adhere to stringent guidelines that dictate the materials used, the manufacturing processes involved, and the rigorous testing methods to ensure axle bolts can withstand extreme conditions. The emphasis on performance integrity is paramount; therefore, regular assessments through tensile strength tests, fatigue testing, and exposure to varying temperatures help in verifying that axle bolts meet or exceed safety regulations.

**Tips:** When selecting axle bolts for your vehicle, always look for those that meet recognized industry standards, such as ISO or SAE. Additionally, ensure that the bolts have undergone comprehensive testing to verify their durability. This can greatly reduce the risk of failure under high-stress conditions.

Moreover, advancements in technology have resulted in enhanced testing protocols, including digital simulations and real-world stress tests, which help predict long-term performance. These innovations ensure that only the most reliable axle bolts make it to market, contributing significantly to overall vehicle safety. Regular maintenance checks are also essential; inspecting axle bolts periodically can identify wear and potential issues before they escalate.

**Tips:** Consider keeping a log of your vehicle’s maintenance history, and don't hesitate to consult with a professional if you notice any signs of wear on your axle components.

| Dimension | Standard | Testing Method | Durability Rating | Performance Score |

|---|---|---|---|---|

| Diameter (mm) | ISO 9001 | Tensile Strength Test | Grade 10.9 | 98% |

| Thread Pitch (mm) | DIN 13 | Torque Test | Grade 12.9 | 95% |

| Length (mm) | ASTM A325 | Fatigue Test | Grade 8.8 | 92% |

| Coating Type | ISO 10683 | Salt Spray Test | Zinc Coated | 99% |

As we enter 2023, the automotive industry is witnessing groundbreaking advancements in axle bolt technology, playing a crucial role in enhancing vehicle safety and performance. Innovative materials such as carbon fiber composites and advanced alloys are being utilized to produce higher-strength and lighter axle bolts, addressing the demand for more efficient vehicles. These modern materials not only improve durability but also contribute to better fuel efficiency, making vehicles safer during operation.