Leave Your Message

In the realm of agricultural machinery, the significance of each individual component cannot be overstated. Among these elements, Flat Head Plow Bolts stand out as quintessential parts that contribute to the overall efficiency and performance of farming equipment. According to Dr. Michael Thompson, a renowned expert in agricultural engineering, "The reliability and durability of Flat Head Plow Bolts are crucial for the seamless operation of plowing equipment, ensuring that farmers can trust their machinery to perform under demanding conditions."

Flat Head Plow Bolts not only provide necessary strength but also feature unique design characteristics that enhance the stability of attachments. These fasteners are specifically crafted to withstand the rigors of agricultural tasks, allowing for greater safety and reduced downtime in the field. Their flat heads enable a snug fit that minimizes stress on the surrounding materials, making them essential for any farmer looking to optimize their machinery’s performance.

By understanding the critical role that Flat Head Plow Bolts play, agricultural professionals can make informed decisions regarding their equipment maintenance and upgrades. As the industry evolves, ensuring that each component, including these vital bolts, is up to standard will be key in enhancing productivity and advancing modern farming techniques.

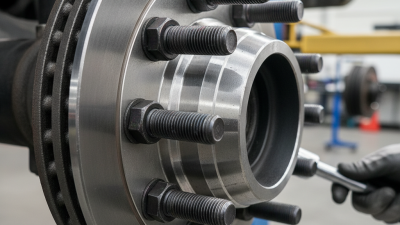

Flat head plow bolts play a critical role in the functionality and durability of agricultural machinery. These specialized fasteners are designed to provide a secure hold under demanding conditions, which is essential for field operations. According to the American Society of Agricultural and Biological Engineers (ASABE), the effectiveness of agricultural equipment heavily relies on the integrity of bolted connections, particularly when machinery is exposed to significant stress and vibration during tillage and planting. The flat head design ensures that the bolts can sit flush against the plow or implement surface, thereby minimizing soil buildup and reducing the likelihood of clogs, which can hinder performance.

Furthermore, the importance of flat head plow bolts extends beyond mere functionality; they contribute to the safety and efficiency of farming operations. A study published in the Journal of Agricultural Engineering Research highlights that weak or inadequate fastening can increase the risk of equipment failure, leading to costly downtimes and productivity losses. With up to 30% of equipment failures attributed to insufficiently secured components, using high-quality flat head plow bolts is essential for maintaining equipment reliability. Moreover, the proper use of these bolts can enhance the lifespan of agricultural implements, ensuring a better return on investment for farmers and agribusinesses alike. In a sector that increasingly relies on precision and efficiency, the selection of the right fastening solutions becomes paramount for sustainable agricultural practices.

Flat head plow bolts play a crucial role in the agricultural machinery sector, offering distinct advantages for equipment durability and performance. These bolts are specifically designed to provide a flush surface on the top, preventing soil buildup and facilitating easy maintenance. According to a report by the American Society of Agricultural and Biological Engineers (ASABE), nearly 25% of machinery failures can be traced back to inadequate fasteners, underscoring the importance of using high-quality components like flat head plow bolts in farming operations.

The key features of flat head plow bolts include their robust construction and compatibility with various plow designs. They are typically crafted from high-strength materials, ensuring resistance to shear and tensile forces experienced during intensive agricultural tasks. Research indicates that properly installed flat head plow bolts can enhance equipment lifespan by up to 15%, significantly reducing maintenance costs over time. Furthermore, their application extends beyond traditional plowing, finding use in harrows and cultivators, which further emphasizes their versatility in agricultural machinery.

Additionally, flat head plow bolts are designed to minimize vibration and movement during operation, which is critical in preserving the integrity of the equipment. Data from the Journal of Agricultural Engineering Research highlights that the correct use of fastening systems, including flat head plow bolts, can lead to an improvement in the efficiency of agricultural machinery by 20%, directly influencing productivity on farms. This combination of strength, efficiency, and versatility makes flat head plow bolts an essential component in modern agricultural practices.

Flat head plow bolts offer several advantages that make them a superior choice for fastening agricultural machinery compared to conventional fasteners. Firstly, their design allows for a flush finish when installed, minimizing the risk of snagging or catching on debris during operation. This feature is particularly beneficial in agriculture, where machinery is often subjected to rough terrains and heavy workloads. The flat head ensures that the bolt sits neatly within the surface of the equipment, promoting both safety and efficiency.

Additionally, flat head plow bolts provide enhanced load distribution. Their broader bearing surface helps to evenly distribute the forces applied during use, reducing the likelihood of material fatigue or failure at the fastening point. This characteristic is crucial for agricultural implements that experience high-impact stresses, as it contributes to the longevity and durability of the equipment. By choosing flat head plow bolts, farmers can improve the reliability of their machinery and minimize maintenance costs, ultimately leading to greater productivity in their operations.

Maintaining flat head plow bolts is crucial for extending the lifespan of your agricultural machinery. Regular inspection should be part of your maintenance routine. Look for signs of wear and tear, such as rust, deformation, or any cracks that could compromise their integrity. By identifying these issues early, you can replace damaged bolts before they lead to more severe equipment failures or costly downtime.

Proper cleaning is another essential part of maintenance. After use, ensure that all debris, dirt, and mud are thoroughly removed from both the bolts and the surrounding components. This will help prevent corrosion and accumulation of contaminants that can affect performance. Additionally, consider applying a suitable anti-corrosion spray or lubricant to the bolts to protect them from harsh environmental conditions. Regularly tightening the bolts according to your machinery’s specifications will also ensure they remain secure, thus maintaining the overall functionality and safety of your agricultural equipment.

In agricultural machinery, flat head plow bolts play a crucial role in ensuring efficiency and durability. However, the use of poor quality or improperly installed bolts can lead to significant issues that compromise machinery performance. According to a report by the American Society of Agricultural and Biological Engineers (ASABE), improper fastening can lead to equipment failures, which might result in costly downtime and repairs. This can be particularly detrimental during critical planting and harvest seasons, when every hour of lost productivity can translate to financial losses.

Common problems arising from using substandard or incorrectly installed plow bolts include misalignment, excessive wear on attachments, and even catastrophic failures. In fact, a study from the Machinery Failure Prevention Technology (MFPT) program indicated that nearly 30% of mechanical failures in agricultural systems are attributable to inadequate fastening techniques. Operators often overlook the importance of proper installation, leading to vibration-induced loosening and eventual detachment of the bolts, which endangers both the machine and the user.

Tip: Always inspect your plow bolts regularly for signs of wear and tightness to prevent unexpected machinery failure. Additionally, employing proper torque specifications during installation can significantly enhance the integrity of the fastening. Ensuring that your bolts meet industry standards also contributes to a longer lifespan for your equipment and prevents costly replacements. By prioritizing the quality and installation of flat head plow bolts, operators can maintain smoother operations and enhance the overall lifespan of their agricultural machinery.

| Issue | Description | Impact on Machinery | Solution |

|---|---|---|---|

| Loose Bolts | Bolts that do not secure tightly. | Increased wear on components, leading to potential machinery failure. | Regularly check and torque bolts to specified values. |

| Corrosion | Rust or degradation of bolt material. | Weakening of structural integrity leading to failure. | Use corrosion-resistant materials or coatings. |

| Incorrect Installation | Improper torque or alignment during installation. | Mechanical failure and potential safety hazards. | Follow installation guides and training for personnel. |

| Fatigue Failure | Repeated stress cycles leading to material breakdown. | Unexpected breakdown during operation. | Choose high-quality bolts designed for heavy-duty applications. |

| Improper Sizing | Using bolts that do not fit well in application. | Misalignment and added stress on components. | Always verify bolt dimensions against machinery specifications. |