Leave Your Message

Wheel Lug Bolts play a crucial role in vehicle safety. These small yet powerful components secure your wheels to the vehicle. When driving, the stress on these bolts increases significantly. If they fail, the consequences can be disastrous.

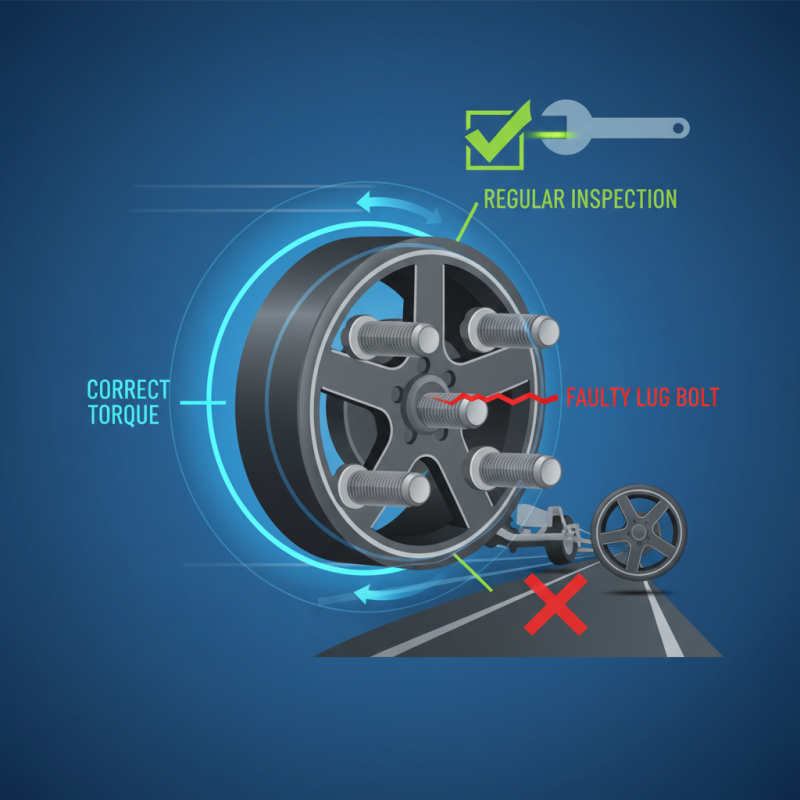

Imagine driving down a highway. Suddenly, a wheel detaches due to faulty lug bolts. This can result in loss of control, accidents, and serious injuries. Regular inspections of Wheel Lug Bolts can prevent such scenarios. However, many drivers overlook this important task.

Each bolt must be torqued to the correct specifications. This ensures they hold the wheel firmly. Neglecting their maintenance can lead to uneven wear and potential failure. A simple mistake can have grave outcomes. Understanding the significance of Wheel Lug Bolts is vital for every vehicle owner.

Wheel lug bolts play a crucial role in vehicle safety. They secure the wheels to the vehicle, ensuring stability during operation. If these bolts fail, the consequences can be dire. Loose wheels can cause loss of control, leading to accidents. Regular checks are necessary, but often overlooked by many drivers.

In vehicle design, lug bolts must meet strict safety standards. Engineers test them for strength and durability. However, not all manufacturers prioritize quality equally. Some may cut corners, using inferior materials. This can compromise safety. Educating consumers on the importance of high-quality bolts is essential. Many people may not know the difference until it’s too late.

Proper installation is another key factor. Over-tightening can damage the bolts. Under-tightening leaves them vulnerable. Ensuring correct torque specifications is vital. Yet, many skip this important step. Awareness and training around lug bolt maintenance can greatly improve vehicle safety. It’s a detail that should not be ignored.

| Dimension | Details |

|---|---|

| Material | High-Strength Steel or Alloy |

| Standard Torque Specification | 80-100 ft-lbs (Varies by vehicle) |

| Failure Mode | Stripping or Shearing |

| Common Diameter | M12, M14, or M16 (Metric) |

| Safety Standard Reference | SAE J2530, ISO 3767 |

| Recommended Replacement Interval | Every 50,000 miles or if damaged |

| Testing Requirements | Tensile Strength, Fatigue Testing |

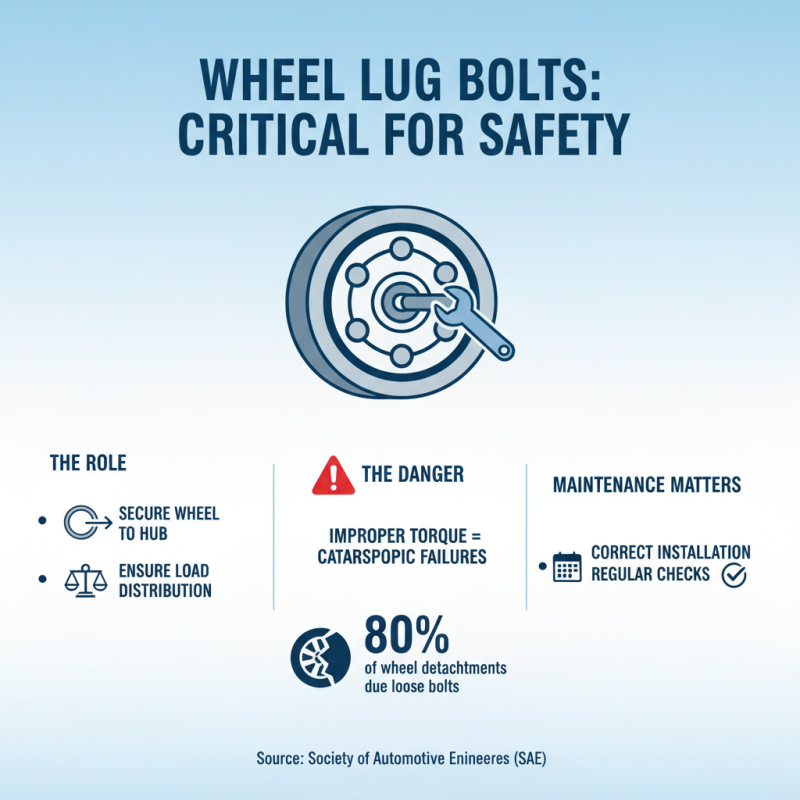

Wheel lug bolts play a vital role in vehicle safety. They secure the wheel to the hub and ensure proper load distribution. According to the Society of Automotive Engineers, improper torque on lug bolts can lead to catastrophic failures. In fact, approximately 80% of wheel detachments are due to loose or improperly installed bolts. This highlights the significance of correct installation and maintenance.

When the bolts are torqued correctly, they help distribute the vehicle's weight evenly across all wheels. This distribution affects performance and ride quality. Uneven load can cause excessive wear on tires and suspension components. A study showed that a 2% increase in load imbalance could reduce tire life by nearly 20%. Monitoring lug bolt integrity is crucial. Skipping regular checks can lead to dangerous situations.

Despite their importance, many drivers overlook lug bolt maintenance. A simple visual inspection can catch issues early. Signs like rust or dirt buildup can indicate problems. There's no room for complacency when it comes to vehicle safety. Take time to understand the critical role of wheel lug bolts in maintaining your vehicle's performance and reliability.

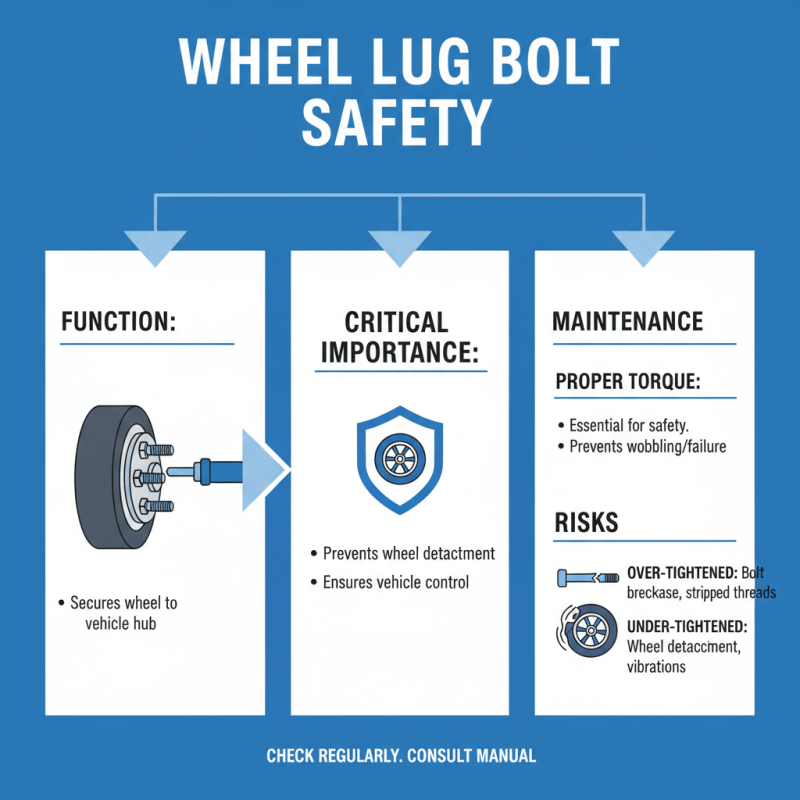

Wheel lug bolts are crucial for maintaining vehicle safety. They secure the wheels to the vehicle, ensuring stability during operation. However, several common factors can lead to their failure. Over-tightening and under-tightening are frequent issues. Inconsistencies in torque can cause the bolts to stretch or break under pressure. A study by the Society of Automotive Engineers indicated that over 50% of wheel bolt failures occur due to improper torque settings.

Temperature changes can impact lug bolt integrity as well. This can happen when driving through varied climates or even on hot surfaces. Repeated cycles of heating and cooling may weaken the bolts. It is vital for drivers to regularly check their vehicles for signs of wear or looseness in lug bolts.

**Tips:** Always use a calibrated torque wrench when installing wheels. Regularly inspect lug bolts for any signs of damage or rust. Remember to recheck the tightness after the first 50 miles of driving post-installation. Ignoring these simple practices could compromise your safety on the road.

Wheel lug bolts are vital for ensuring the safety of a vehicle, as their failure can lead to serious accidents. The chart above illustrates the common causes of wheel lug bolt failure, showing that over-torquing is the most prevalent issue. Understanding these causes can help vehicle owners take preventive measures to maintain safety on the road.

Wheel lug bolts are critical for vehicle safety. They secure the wheels to the hub, ensuring that wheels do not detach while driving. Maintaining proper lug bolt torque is essential to prevent accidents. Over-tightened or loose bolts can lead to unintended consequences.

Many industry standards dictate lug bolt testing methods. These methods assess their strength and durability under various conditions. For instance, they are subjected to torque tests, vibration tests, and fatigue analyses. These tests help manufacturers ensure reliability. However, not all bolts perform equally. Some may show signs of wear and tear sooner than expected. It's crucial to consider these factors when choosing lug bolts for your vehicle.

**Tip:** Always check your lug bolts after a tire change. A quick visual inspection can save you from potential failures.

Remember that regular maintenance is key. Inspect bolts regularly and look for any signs of damage or corrosion. This can help you catch issues before they escalate. If you notice anything unusual, consider replacing them sooner rather than later.

Maintaining wheel lug bolts is crucial for vehicle safety. Regular inspections can prevent accidents caused by wheel detachment. Owners should check these bolts frequently to ensure they are tight and not corroded. A loose bolt may seem minor, but it can lead to severe issues. Drivers often overlook this aspect until something goes wrong.

Proper torque specifications are vital. Each vehicle has its own requirements, detailed in the owner's manual. Using an accurate torque wrench is essential. Some might use feel or guesswork, which can be dangerous. A bolt that is too tight can break, while one that is too loose can lead to failure. Both situations require careful attention.

Environmental factors can also impact lug bolts. Exposure to road salt, moisture, and dirt can lead to rust. When rust forms, it compromises the bolt's strength. A thorough cleaning during maintenance can help mitigate this. Coating bolts with anti-corrosion solutions is another good practice. However, some individuals may skip this step, not realizing the long-term consequences. Regular maintenance is not just a guideline; it's a necessity for safety.