Leave Your Message

Choosing the right wheel bolts for your vehicle is crucial for safety and performance. Wheel bolts play a vital role in securing your wheels to the vehicle. Improperly chosen bolts can lead to serious accidents. It is essential to understand the specifications and types available.

Consider factors like bolt length and thread pitch. Each vehicle has specific requirements. Many drivers overlook the importance of matching these specifications. Incorrect bolts can cause vibrations or even wheel detachment. Are you sure your choice is correct?

Additionally, the material of the wheel bolts matters. Steel and aluminum bolts have different strengths. Aesthetic choices can also distract from functionality. Some may prefer flashy options, but durability should be the priority. Reflecting on your choices can prevent potential issues on the road.

When it comes to vehicle safety, wheel bolts play a crucial role. These small components are often overlooked. However, they are integral to securing your wheels firmly. If the bolts are not installed properly, it can lead to serious consequences. Loose or damaged bolts can cause wheels to detach while driving, posing a severe risk to you and others on the road.

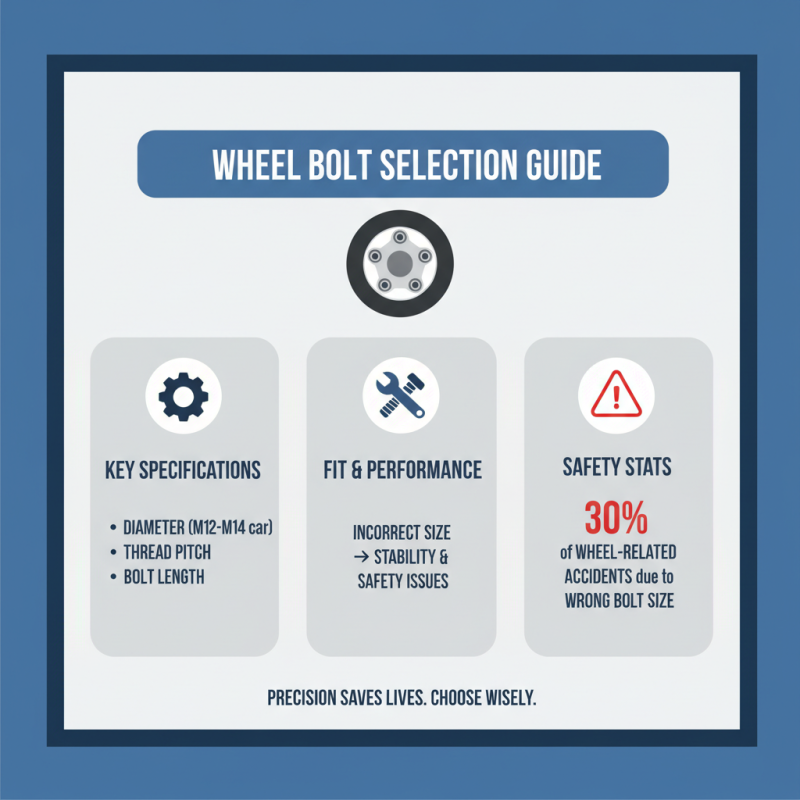

Choosing the right wheel bolts requires careful consideration. Not all bolts are created equal. It’s vital to check the specifications for your vehicle. Factors such as bolt length, thread pitch, and material should not be ignored. Many people underestimate these details, thinking any bolt will do. This error can lead to unsafe driving conditions and expensive repairs.

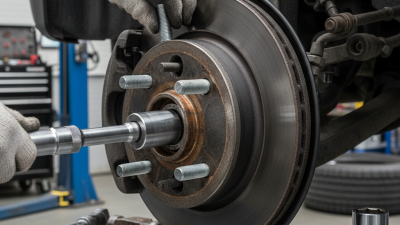

Many drivers fail to replace worn-out wheel bolts. Ignoring signs of rust or corrosion can be a mistake. Regularly inspecting these components is essential. Sometimes, it's easy to overlook such minor details in vehicle maintenance. Yet, addressing these small elements can save lives and prevent accidents. Taking the time to ensure your wheel bolts are in top condition is a step toward safer driving.

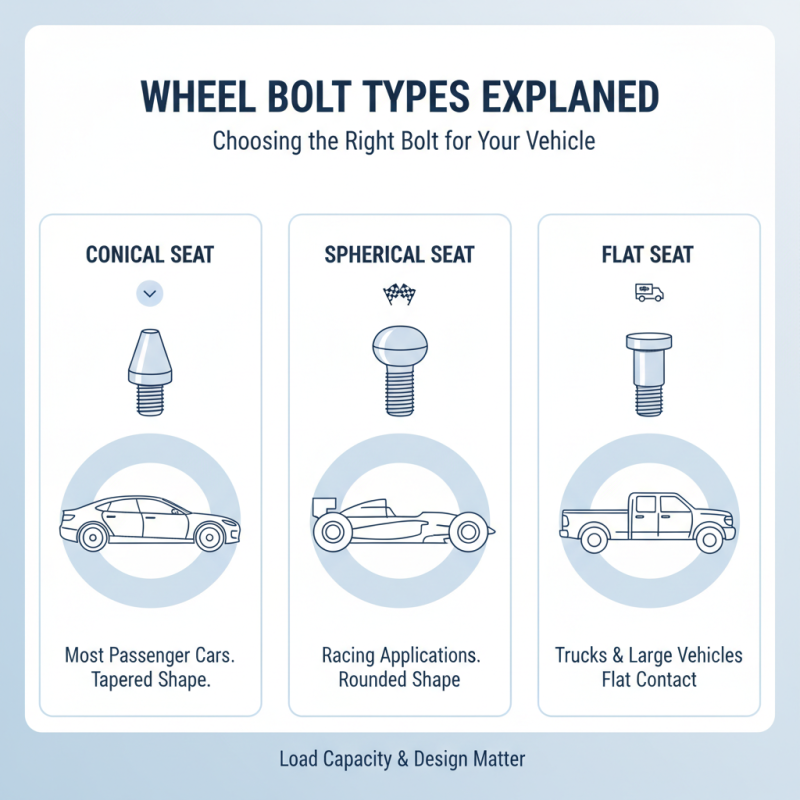

When choosing wheel bolts, understanding their types is crucial. Different vehicles require specific bolts based on design and load capacity. Common types include conical, spherical, and flat seat bolts. Conical bolts are popular for most passenger cars. Spherical bolts are often used in racing applications. Flat seat bolts are typically found in larger vehicles, like trucks.

**Tip:** Always check your vehicle's manual for the correct specifications. Incorrect sizes can lead to poor performance. Measuring the bolt length and diameter can prevent mistakes. You might find that some bolts don’t fit perfectly into the wheel hub. This can be a concern for your safety.

Some materials are stronger than others. Steel bolts offer durability, while aluminum bolts are lighter. Consider where you drive. If you frequently encounter rough terrains, steel bolts might be a better option.

**Tip:** Regularly inspect your wheel bolts for wear. Signs of rust or deformation should not be ignored. A neglected bolt can lead to wheel detachment. Keep in mind that not all bolts are meant for your specific wheels. Mixing types could lead to instability.

When selecting wheel bolts for your vehicle, key specifications are critical. The diameter and thread pitch of bolts influence their fit and performance. Common sizes for passenger cars typically range from M12 to M14. An incorrect size can lead to issues in stability and safety. According to technical reports, improper bolt dimensions can cause up to 30% of wheel-related accidents. This figure highlights the importance of precision in your choice.

Strength is another vital aspect. Look for bolts with a high tensile strength rating, often measured in tons per square inch. Many industry professionals recommend using bolts rated for at least 10.9. This rating ensures they can withstand high torque and prevent failure under stress. Moreover, the material used, often aluminum or carbon steel, affects longevity. Carbon steel tends to rust, while aluminum resists corrosion but may not be as strong. Each material has its trade-offs, prompting the need for careful consideration.

Beyond specifications, ensure proper installation. Even quality bolts can fail if not installed correctly. Torque settings must align with manufacturer recommendations to avoid stripping threads. A maintenance report revealed that around 15% of drivers ignore these guidelines, leading to potential safety hazards. Continuous education on wheel bolt selection enhances proactive vehicle maintenance strategies.

When selecting wheel bolts for your vehicle, there are common pitfalls to avoid. One major mistake is not checking the specifications. Each vehicle has unique requirements. Using the wrong size can lead to serious issues. Measure your existing bolts carefully. Don't rely solely on guesswork.

Another common error is ignoring the material. Different metals have varying strengths and weights. Stainless steel offers durability but may be heavier. Aluminum is lighter but not as robust. Choose based on your vehicle's needs and driving habits.

Lastly, don’t overlook the importance of thread condition. Worn or damaged threads can cause bolts to loosen over time. Inspect both the wheel and bolt threads before installation. Ensure a snug fit. Failing to do so could result in accidents. Stay vigilant and informed about what you need.

Wheel bolts play a crucial role in ensuring your vehicle's safety and performance. Regular maintenance can significantly enhance their longevity. Many experts recommend inspecting wheel bolts every 6,000 miles to prevent premature wear and tear. A recent study indicates that improper torque can reduce bolt lifespan by up to 30%. This is something every vehicle owner should consider.

One essential tip is to regularly check the torque settings. Over-tightening can lead to bolt stretch, while under-tightening may cause loosening. Both conditions jeopardize safety. Also, consider using a torque wrench for precise measurements. Did you know that a torque wrench can help maintain torque within a 5% margin of error? This small investment pays off in the long run.

Cleanliness is vital. Remove dirt and corrosion from bolt threads. This can prevent galvanic corrosion, which can weaken the bolts. Using a wire brush can be effective. Additionally, applying anti-seize lubricant can minimize friction and ensure smooth removal. Remember, neglecting maintenance can lead to costly repairs or even accidents. Pay attention, and your wheel bolts will thank you.