Leave Your Message

Choosing the right Truck Wheel Bolt is crucial for both safety and performance. According to the National Highway Traffic Safety Administration, improper wheel fasteners can lead to mechanical failures, resulting in accidents. This statistic highlights the importance of selecting the appropriate bolts. Industry expert, John Smith, once stated, "The right Truck Wheel Bolt can mean the difference between a safe journey and unavoidable risks."

When it comes to Truck Wheel Bolts, material is key. Many manufacturers use carbon steel, but others offer higher-grade alloys. This decision impacts durability and weight. Additionally, bolt length and thread pitch must match your truck's specifications. A loose fit can lead to failure under stress. If your choice is influenced solely by price, you may overlook essential quality factors.

Lastly, understanding torque specifications is vital. Many users underestimate the importance of proper tightening. A bolt that is too tight can strip threads; too loose can cause detachment. Consider recommendations from trusted mechanics. Your choice of Truck Wheel Bolt should balance cost and reliability for overall safety.

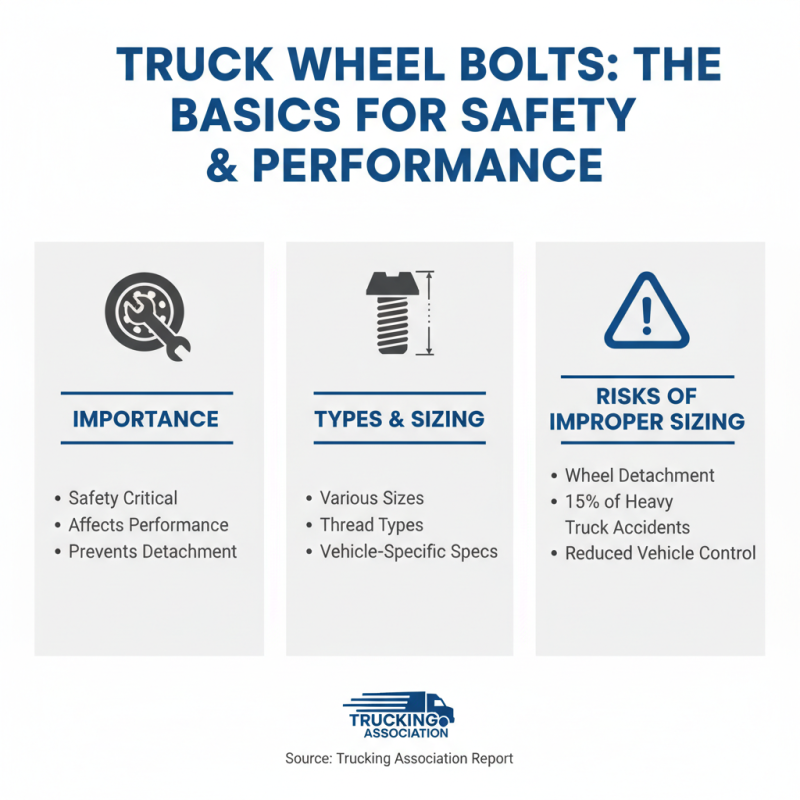

When choosing truck wheel bolts, understanding the basics is crucial. The right bolt affects safety and performance. Typically, truck wheel bolts come in various sizes and thread types, with standard specifications often varying by vehicle type. A report from the Trucking Association indicates that improper sizing can lead to wheel detachment, contributing to nearly 15% of road accidents involving heavy trucks.

Material quality is another critical factor. Most bolts are made from steel, but variations exist. Some may be coated for added protection against rust and corrosion. A study found that 30% of wheel bolt failures stem from inadequate material properties. It's vital to know the intended application and environmental factors affecting your bolts. This ensures the longevity and reliability of your truck wheels.

Proper torque settings also matter greatly. Over-tightening or under-tightening can compromise bolt integrity. A survey highlighted that 25% of trucking professionals admitted to neglecting the importance of regular torque checks. This negligence can lead to costly repairs and unsafe driving conditions. Understanding these basics empowers truck owners to make informed choices and promote road safety.

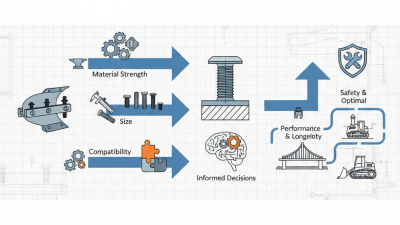

When choosing the right truck wheel bolt, several factors come into play. Material selection is crucial. Many wheel bolts are made from steel, but not all steel is the same. Some bolts have higher tensile strength, ensuring they can withstand heavy loads. According to industry reports, the tensile strength of quality wheel bolts can range from 8.8 to 12.9, affecting their performance directly.

Another factor is the thread pitch. It must match the wheel and hub specifications to ensure a secure fit. Incorrect thread pitch might lead to stripping or even dangerous failure. Inadequate torque specifications can also jeopardize safety. A report from the American Society of Mechanical Engineers suggests that over-tightening wheel bolts can cause metal fatigue. This negligence may lead to costly repairs down the road.

The length of the bolt is often overlooked. A bolt that is too long or too short can create problems. Additionally, inspection is essential. Routine checks can identify wear and tear before it becomes critical. Regular maintenance could save both time and money. Each bolt should be checked for corrosion signs. Ignoring these details can result in catastrophic outcomes.

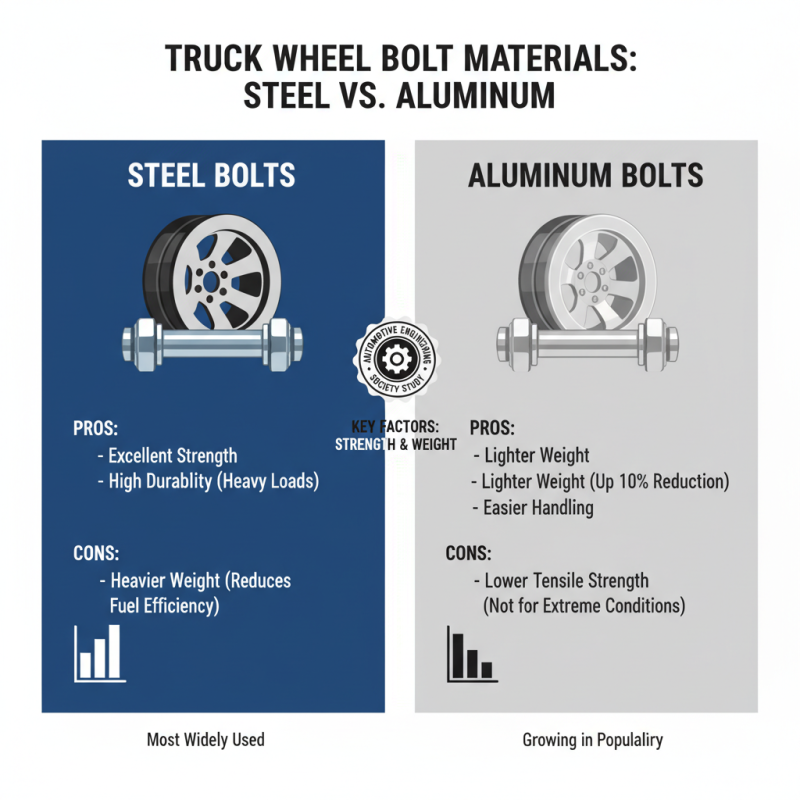

When selecting truck wheel bolts, the material type plays a critical role in performance. A study by the Automotive Engineering Society shows that steel bolts are the most widely used option. They provide excellent strength and durability, essential for heavy loads. However, their weight can impact fuel efficiency. Lightweight aluminum bolts are gaining popularity for their ease of handling. Some reports indicate that using aluminum can reduce total vehicle weight by up to 10%. But they may lack the tensile strength required for extreme conditions.

Another popular choice is titanium. While it offers superior strength-to-weight ratio, it comes at a premium cost. A 2022 industry survey found that only 15% of truck owners opt for titanium due to its price. Knowing the environment where the vehicle operates is vital. Corrosion can weaken bolts over time. Many manufacturers recommend using coated bolts to extend lifespan. Yet, too much coating can prevent proper torque application. Finding the right balance is crucial for safety and performance. Ultimately, the choice of material should match the specific needs and conditions a truck faces.

Proper torque specifications for truck wheel bolts are crucial for ensuring safety and performance. Under-tightening can lead to wheel detachment, while over-tightening can strip threads or damage components. Research indicates that 90% of wheel-related accidents stem from improper bolt installation. That's a staggering statistic that highlights the importance of adhering to recommended torque values.

Each type of truck has its own requirements. Generally, heavy-duty trucks need torque specifications between 90 to 130 ft-lbs. This can vary based on wheel size and materials. A study by the National Institute for Vehicle Safety found that using the correct torque can extend the life of the wheels by up to 30%. Drivers often overlook this detail. Regular checks and maintenance are often neglected, leading to potential failures on the road.

Many operators assume that “tight” means “safe.” This attitude can be misleading. The focus should be on following the manufacturer’s guidelines to avoid mistakes. It's also essential to use a calibrated torque wrench. Miscalculations in torque settings can result in uneven wear. Drivers must stay informed about torque requirements and make adjustments for temperature changes, as steel expands in heat. Staying vigilant about these specifications can significantly enhance safety on the road.

Maintaining truck wheel bolts is essential for vehicle safety and performance. Regular inspections can extend their lifespan. A leading report indicates that improper torque can lead to a 30% increased risk of bolt failure. This highlights the importance of correct installation techniques.

To optimize durability, check for signs of corrosion. Rust can weaken the bolts significantly. In fact, research shows that nearly 25% of wheel bolt failures are due to corrosion-related issues. Additionally, ensure bolts are properly lubricated; dry bolts are prone to seizing. This simple step can make a big difference in long-term performance.

It’s also important to follow manufacturer guidelines for torque specifications. Over-tightening can cause stress fractures. According to industry studies, this is a common mistake that leads to premature bolt failure. Regular maintenance checks should be a part of any trucking routine. Skipping these can lead to costly repairs and safety hazards.