Leave Your Message

Choosing the right Roller Bolt can feel overwhelming. With various options available, it’s crucial to understand your specific needs. According to industry reports, over 35% of users face difficulties in selecting suitable fasteners. Missteps in this area can lead to safety issues and decreased efficiency.

Roller Bolts come in different materials and designs. Each type serves distinct purposes. For instance, a stainless steel roller bolt provides durability in harsh environments, while nylon options may be more lightweight. It's essential to weigh these factors carefully. Sometimes, the cheapest option isn't the best choice. Investing in quality components can prevent costly repairs later.

Research suggests that over 25% of projects suffer delays due to improper fastener choices. Users often overlook the significance of load-bearing capacity and installation requirements. A thorough understanding of these elements will simplify the decision-making process. Reflect on both the immediate and long-term implications of your selection. Your choice of a Roller Bolt could define the success of your project.

Roller bolts are vital components in various applications. They provide secure fastening while allowing for easy adjustments. Understanding how they function is crucial for selecting the right type. Essentially, roller bolts use a cylindrical mechanism to engage and disengage, offering reliable performance. They are often employed in machinery, furniture, and even automotive settings.

When choosing a roller bolt, consider the material. Different environments may require specific materials to resist corrosion and wear. Make sure the bolt can endure the stresses of your application. Think about load capacity as well. Not all bolts handle the same weight. A mismatch here can lead to failures.

Pay attention to the installation process. Some require specialized tools, while others are user-friendly. If you're unsure, consult with experts or reference materials. This knowledge can prevent costly mistakes. Lastly, always verify the specifications before making a purchase. Errors at this stage can lead to frustration later.

Choosing the right roller bolt requires careful consideration of your specific needs. Start by assessing the weight and size of the items you plan to secure. Heavy and large objects need stronger bolts that can withstand pressure without bending. For lighter installations, you might not need such robust options. Also, consider the environment where these bolts will be used. Humidity and exposure to elements can affect durability.

Another factor is the ease of installation. Some roller bolts require special tools or skills, which might be a challenge for DIY enthusiasts. Think about the materials used in the bolt. Stainless steel and coated options can offer better resistance to rust. When unsure, it can be helpful to consult with a knowledgeable person. Mistakes happen often, especially if choices are made too quickly. It can lead to frustrating outcomes later on. Prioritize quality and fit over cost to avoid unnecessary troubles.

When selecting a roller bolt, material choice heavily impacts durability and strength. Steel is a common and reliable option. According to industry reports, steel rollers can support loads exceeding 1,200 pounds. This makes them suitable for heavy-duty applications like industrial machinery. However, using low-grade steel can lead to premature wear and failure. It is essential to analyze the steel grade and workmanship.

Alternatively, stainless steel offers resistance to corrosion. It’s perfect for outdoor or humid environments. The durability of stainless steel bolts is well-documented; they can last up to three times longer than traditional steel in harsh conditions. Yet, they may be more expensive. Cost considerations should align with long-term usage expectations.

Plastic roller bolts are lightweight and resistant to corrosion. They work well in non-load bearing applications. However, they might not endure high pressures or extreme temperatures. Choosing the right material involves balancing cost, performance, and environmental factors. Reflect on what matters most for your specific circumstances.

| Tip Number | Tip Description | Key Considerations | Material Recommendation |

|---|---|---|---|

| 1 | Identify the load requirements | Understand the weight the roller bolt needs to support. | Steel for heavy loads |

| 2 | Consider environmental factors | Humidity, temperature changes, and exposure to chemicals can affect material choice. | Stainless steel for corrosion resistance |

| 3 | Check compatibility with existing hardware | Ensure that new bolts fit well with existing components. | Aluminum for lightweight applications |

| 4 | Assess the roller bolt's lifespan | Determine how long the bolt needs to last based on usage. | High-strength steel for longevity |

| 5 | Evaluate the cost-effectiveness | Balance quality with price for optimal choice. | Mild steel for budget-friendly options |

| 6 | Research industry standards | Stay compliant with regulations and safety measures. | Industry-standard materials |

| 7 | Consider installation requirements | Factor in the complexity of installation and tools needed. | Easy-to-install materials |

| 8 | Look for customer reviews | Gain insight from others who have used the product. | Highly-rated materials |

| 9 | Consider weight distribution | Ensure that the load is evenly distributed across bolts. | Reinforced materials |

| 10 | Consult a specialist if needed | Seek expert advice for specific projects. | Professionally recommended materials |

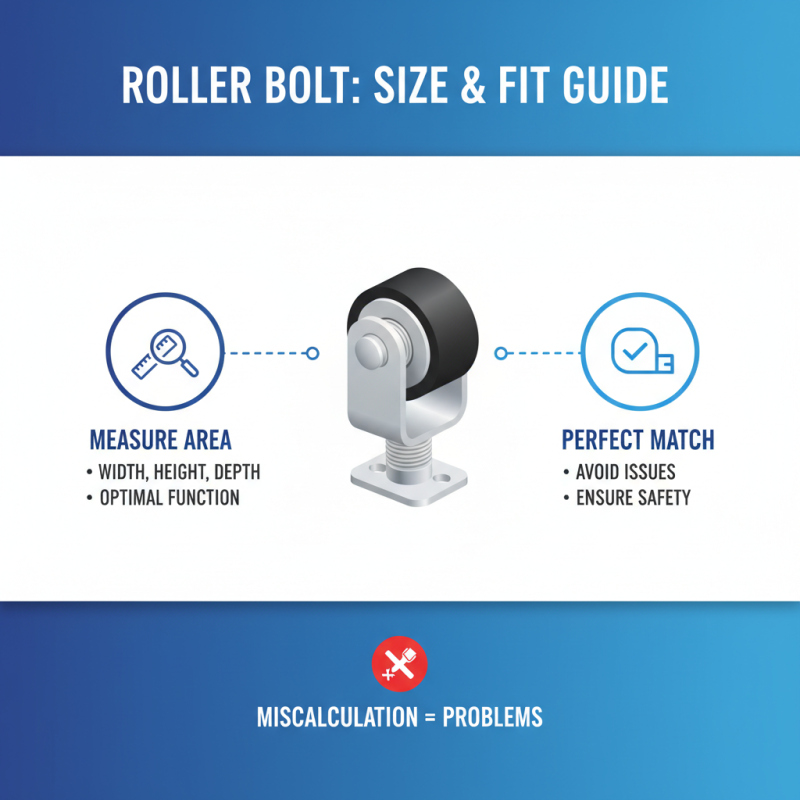

When selecting a roller bolt, size and dimensions play a crucial role. A perfect fit ensures optimal function and safety. Measure the area where the roller bolt will be installed. Consider the width, height, and depth required for your application. A miscalculation can lead to significant issues. It’s essential to check whether your chosen roller bolt matches these measurements.

The installation space can be deceptive. You might think a standard size will suffice, but sometimes it won’t. Experience shows that attention to detail is key. If the dimensions are off by just a millimeter, it can lead to malfunction. A bolt that is too small won’t hold securely. A bolt that’s too large may not fit at all. Always double-check your measurements. Having a flexible approach can help adjust to unforeseen discrepancies.

Look at the specifications recommended for your project. If you are unsure, consult industry guidelines. They often provide insight on typical sizes for various applications. It’s better to take the time to measure accurately than to rush. Remember, not all projects are the same. Each one may require a unique bolt. This is where careful consideration becomes invaluable.

Installing roller bolts may seem straightforward, but attention to detail is crucial. Proper alignment during installation ensures a secure fit. Misalignment can lead to operational issues, decreasing the lifespan of the bolt. A report from the National Association of Home Builders indicates that improper installations account for 30% of hardware failures in residential properties.

Using appropriate tools is essential. A torque wrench can help achieve the right tightness without over-stressing the materials. Reports suggest that over-tightening can reduce the effectiveness of the roller bolt by up to 25%. It’s important to follow your project’s specifications closely. Following guidelines helps ensure durability and reliability in performance.

Lastly, consider the environment where the bolts will be used. For indoor applications, corrosion resistance might be less critical. However, outdoor uses require specific materials to withstand harsh elements. The American Society for Testing and Materials notes that environmental factors can shorten the lifespan of hardware by up to 40%. Regular inspections can also reveal early signs of wear and tear, allowing for timely replacements.