Leave Your Message

When it comes to choosing the right Wheel Center Cap Bolts for your vehicle, understanding the nuances of functionality and compatibility is crucial. According to industry expert John Smith, a well-known automotive engineer, “Selecting the appropriate Wheel Center Cap Bolts is not just about aesthetics; it plays a fundamental role in vehicle safety and performance.” This insight highlights the importance of considering not only the bolts' appearance but also their specifications and durability.

The right Wheel Center Cap Bolts ensure that your wheel center caps are securely fastened, preventing any potential vibrations or dislodgement while driving. With a variety of materials, sizes, and styles available in the market, it can often feel overwhelming to make the best choice. It's essential to understand the specific requirements of your vehicle and how different bolts can impact both the fit and functionality of your wheel accessories.

Whether you're replacing old bolts or customizing your ride, paying attention to details like thread size, material strength, and resistance to corrosion can make a significant difference. By following expert advice and conducting thorough research, you can confidently select the Wheel Center Cap Bolts that meet your vehicle’s needs, ensuring both style and safety on the road.

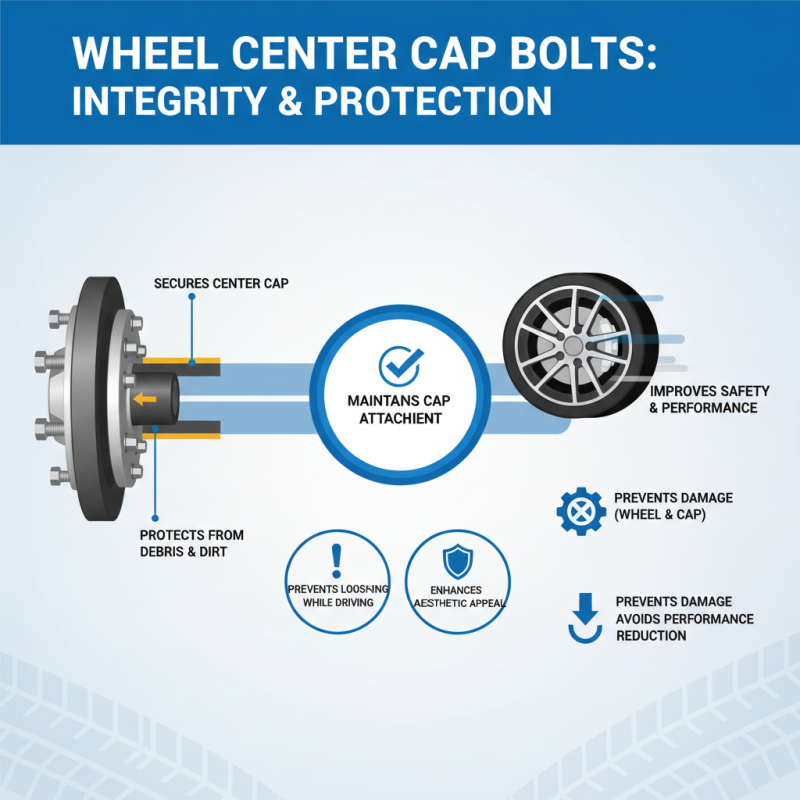

Wheel center cap bolts play a crucial role in the overall integrity of your vehicle's wheels. Their primary purpose is to secure the wheel center cap, which not only enhances the aesthetic appeal of your vehicle but also protects the wheel's components from debris and dirt. These bolts ensure that the center cap remains firmly attached, preventing it from loosening while driving. This functionality is essential as a loose cap can lead to potential damage to both the wheel assembly and the cap itself, thereby affecting performance and safety.

When selecting the right wheel center cap bolts, it's vital to consider several factors. The size, thread pitch, and material of the bolts should match your vehicle's specifications. Using incorrect bolts can lead to complications such as cross-threading or even breakage.

**Tips:** Always refer to your vehicle's manual for detailed specifications on wheel center cap bolts. Additionally, pay attention to the corrosion resistance of the bolts, especially if you live in an area with harsh weather conditions. Investing in high-quality bolts will ensure a longer lifespan and better performance, ultimately contributing to the overall safety and appearance of your vehicle.

Choosing the right wheel center cap bolts is crucial for ensuring the longevity and functionality of your vehicle's wheels. When assessing the specifications of these bolts, three key factors come into play: diameter, thread pitch, and material composition. Firstly, the diameter of the bolts must match the dimensions of the wheel center cap to ensure a secure fit. A bolt that is too small may not hold the cap firmly in place, while one that is too large can cause damaging strain on the bolt and the cap.

Next, the thread pitch plays a vital role in the compatibility and performance of the bolts. The thread pitch refers to the distance between threads and can significantly affect how tightly the bolt can be secured. A proper match in thread pitch between the bolt and the cap is essential for preventing loosening and ensuring stability during driving conditions. It is advisable to consult technical specifications or a professional to determine the correct thread pitch for your vehicle.

Finally, material composition greatly influences the durability and resistance of the wheel center cap bolts. Common materials include steel, aluminum, and stainless steel, each offering varying levels of strength and corrosion resistance. Selecting a material that withstands the specific environmental conditions your vehicle is exposed to—such as moisture, road salt, or extreme temperatures—will prolong the lifespan of the bolts and protect the wheel assembly. By carefully considering these specifications, you can make an informed decision that enhances the safety and performance of your vehicle.

When selecting wheel center cap bolts, understanding compatibility factors associated with your vehicle's make and model is crucial. Different manufacturers design their vehicles with specific dimensions and standards, which can greatly affect the type of bolts that are suitable for use. Start by checking the vehicle’s manual or the specifications provided by the manufacturer to determine the required bolt size, length, and thread pitch. These details are vital in ensuring a secure and safe fitment.

In addition to size, consider the material and finish of the bolts. The environment in which your vehicle operates can influence the wear and tear on these components. For instance, if you frequently drive in wet or corrosive conditions, you may want to select bolts made from stainless steel or those that have a protective coating. Always ensure that the chosen bolts not only fit mechanically but also withstand the environmental challenges to prevent premature degradation. Properly matched bolts will enhance both the functionality and aesthetic of your wheel center caps, providing peace of mind during your drives.

| Vehicle Make | Vehicle Model | Year | Bolt Size (mm) | Thread Pitch (mm) | Material Type |

|---|---|---|---|---|---|

| Toyota | Camry | 2020 | 12 | 1.5 | Steel |

| Honda | Civic | 2019 | 10 | 1.25 | Aluminum |

| Ford | F-150 | 2021 | 14 | 1.5 | Stainless Steel |

| Chevrolet | Silverado | 2022 | 12 | 1.75 | Carbon Steel |

When it comes to selecting the right wheel center cap bolts for your vehicle, understanding the torque requirements is crucial for optimal performance. Proper tightening not only ensures that the caps stay securely in place but also helps to avoid common issues such as vibration, warping, or even damage to the wheel assembly. Each vehicle model typically has a specified torque range for its bolts, and adhering to these guidelines can significantly enhance safety and reliability.

To achieve the correct torque, consider using a torque wrench, which allows for precise adjustments. Before installation, it’s essential to clean the threads of both the bolts and the bolt holes to prevent debris from affecting the fit. It’s also wise to tighten the bolts in a star pattern, which helps distribute pressure evenly and minimizes the risk of damaging components.

Tips: Always consult your vehicle’s manual for the precise torque specifications. Additionally, checking the tightness of the bolts after the initial installation can help identify any loosening that may occur after driving. Regular maintenance checks can prolong the lifespan of your wheel center caps and maintain the overall performance of your vehicle.

To ensure the longevity and performance of wheel bolts, regular maintenance is essential. Start by routinely checking the tightness of the bolts after installation and during regular vehicle maintenance intervals. Over time, vibrations from driving can loosen wheel bolts, leading to increased risk of wheel detachment. Employing a torque wrench to tighten bolts to the manufacturer's specifications will help maintain optimal security and prevent premature wear.

Another crucial maintenance tip is to keep the wheel bolt area clean and free from debris. Dirt and grime can impede proper seating and may lead to rust or corrosion over time. Utilizing a wire brush or cloth to clean the area around the bolts can enhance their performance. Additionally, consider applying a small amount of anti-seize lubricant to the threads of the bolts before installation, which not only aids in easier removal but also protects against oxidation.

Lastly, it’s important to inspect wheel bolts for signs of wear or damage periodically. Look for any cracks, stripping, or deformities that could compromise their strength. If any bolts appear compromised, they should be replaced immediately to maintain the safety and reliability of your vehicle. Consistent attention to these maintenance practices will help prolong the life and improve the performance of your wheel center cap bolts.