Leave Your Message

When it comes to vehicle safety and performance, one crucial yet often overlooked component is the wheel bolt. According to automotive expert Dr. James Carter, "The strength and reliability of a wheel bolt are paramount to ensuring the overall safety of a vehicle." Choosing the right wheel bolt not only affects the stability of your wheels but can also have significant implications for your driving experience.

This comprehensive guide aims to demystify the process of selecting the appropriate wheel bolt for your vehicle. With a multitude of options available, ranging from different materials to varying lengths and thread sizes, understanding the specifications is vital to make an informed choice. Factors such as load rating and corrosion resistance should also be considered to ensure long-lasting performance.

As we delve into the intricacies of wheel bolts, we'll provide you with essential insights and tips to navigate this critical aspect of vehicle maintenance. By equipping yourself with knowledge about wheel bolts, you not only enhance your vehicle's safety but also contribute to its optimal functioning on the road.

When it comes to vehicle safety, the often-overlooked component of wheel bolts plays a crucial role. Wheel bolts are responsible for securing the wheels to the vehicle’s hubs, ensuring stability and control during operation. A loose or damaged wheel bolt can lead to serious consequences, including wheel detachment while driving, which can result in accidents and injuries. Therefore, understanding the specifications and importance of wheel bolts is vital for vehicle owners.

Choosing the right wheel bolts involves considering several factors, including the correct size, thread type, and material composition. Properly fitted bolts reduce the risk of corrosion and maintain the integrity of the connection between the wheel and the vehicle. Additionally, regular inspection and maintenance of wheel bolts can prevent wear and tear, ultimately enhancing overall safety. Regular checks can identify signs of elongation or stripping, which are indicators that bolts may need replacement, thus ensuring the continued safety of your vehicle on the road.

When selecting the right wheel bolt for your vehicle, understanding your vehicle’s specifications is crucial. Each vehicle has its unique set of requirements concerning wheel bolts, often dictated by its make, model, and year. Start by checking your owner's manual, which typically provides detailed information about the correct size, thread pitch, and overall length of the wheel bolts suitable for your vehicle. This step ensures that you avoid any compatibility issues that could arise from using the wrong bolts.

Additionally, it's important to consider the bolt type, such as conical, flat, or spherical seat designs, and how they correspond to the wheels you have. Wheel specifications such as the bolt pattern, also known as PCD (Pitch Circle Diameter), should be meticulously measured. This involves counting the number of bolts and measuring the distance between their centers to ensure they fit perfectly.

Paying attention to these specifications not only enhances the safety and performance of your vehicle but also prolongs the lifespan of both your wheel bolts and the wheels themselves.

When selecting wheel bolts, one of the first decisions to make is whether to go for standard or custom options. Standard wheel bolts typically conform to widely accepted industry specifications, such as those set by the Society of Automotive Engineers (SAE). They are designed to fit a variety of vehicles and often come in different lengths and diameters to accommodate different hub designs. According to a report from the Automotive Industry Standards Council, over 70% of vehicles on the road can be fitted with standard bolts, making them a reliable option for most car owners.

On the other hand, custom wheel bolts are specifically engineered for unique applications or aftermarket enhancements. This option is particularly beneficial for enthusiasts looking to customize their vehicles with specialized wheels that may require non-standard bolt sizes or configurations. A study from the International Journal of Automotive Engineering suggests that custom wheel bolts can enhance performance by ensuring optimal fitment and reducing the risk of failures in high-stress scenarios. For instance, custom bolts can also allow for lighter weight designs, which potentially improve vehicle handling. As the automotive market continues to evolve, understanding the differences between standard and custom wheel bolts is crucial for ensuring both performance and safety for your vehicle.

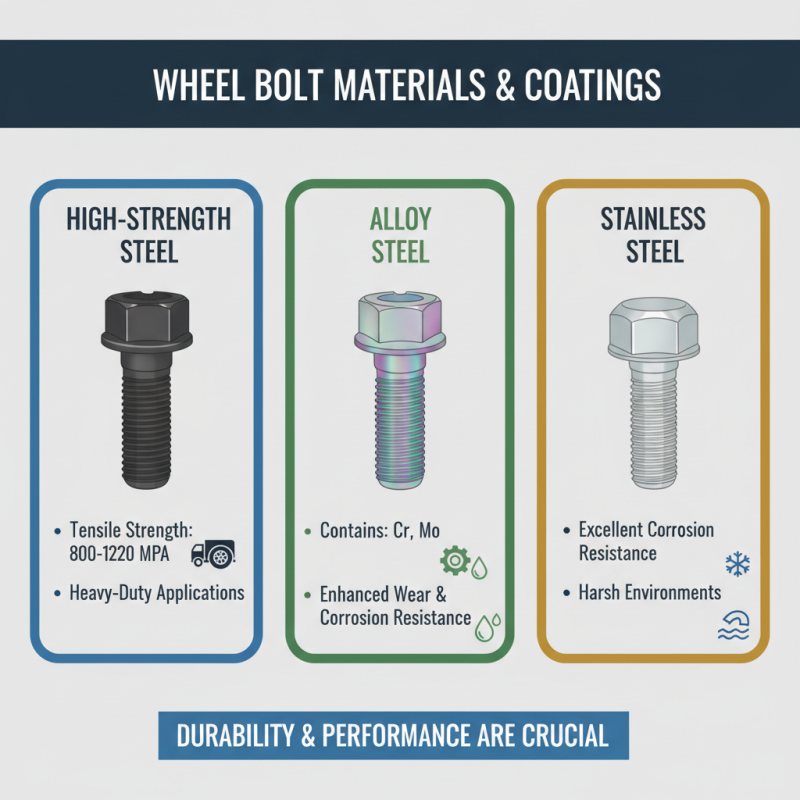

When selecting wheel bolts for your vehicle, the materials and coatings play a crucial role in both durability and performance. Common materials used for wheel bolts include high-strength steel, alloy steel, and stainless steel. High-strength steel is favored for its excellent tensile strength, which typically ranges from 800 to 1200 MPa, making it suitable for heavy-duty applications. Alloy steel, on the other hand, often contains elements like chromium or molybdenum, enhancing its resistance to wear and corrosion. Stainless steel, while less commonly used for bolts due to its lower tensile strength, offers excellent corrosion resistance and is ideal for vehicles operating in harsh environments.

Coatings are equally important, as they protect wheel bolts from rust and enhance their lifespan. Zinc plating is a popular choice due to its cost-effectiveness and ability to provide a barrier against corrosion. For extreme conditions, galvanization offers superior protection, with some reports indicating an increase in lifespan of up to 50% compared to uncoated bolts. Furthermore, special coatings like black oxide or phosphate can improve aesthetics while providing additional protection against the elements.

Tips:

When choosing wheel bolts, ensure that they are compatible with your vehicle's specifications, including length and thread pitch. Regularly inspect the condition of the bolts, especially if you live in an area prone to road salt exposure, as this can significantly increase corrosion rates. Always follow the manufacturer’s torque specifications to prevent over-tightening or under-tightening, which may lead to bolt failure.

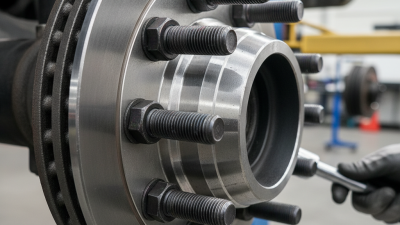

Proper installation and maintenance of wheel bolts are crucial for ensuring the safety and performance of your vehicle. When installing wheel bolts, it's essential to follow a specific torque specification set by the vehicle manufacturer. Using a torque wrench helps in achieving the correct tightness, preventing both under-tightening, which could lead to wheel detachment, and over-tightening, which may cause bolt or stud damage. Always start by hand-tightening bolts in a crisscross pattern to ensure even distribution of pressure before using the torque wrench for final tightening.

Regular maintenance checks on wheel bolts can significantly enhance their longevity and performance. Inspect the bolts periodically for signs of wear, such as rust or deformation, and replace them if necessary. Cleaning the threads of the bolts and the hub surfaces is also advisable to remove any dirt or corrosion that could affect their grip. Additionally, after driving for a short distance post-installation, it is wise to re-check the torque settings to ensure that the bolts have settled correctly and maintain their tightness. Proper care and maintenance of wheel bolts not only prolong their lifespan but also contribute to safer driving experiences.