Leave Your Message

In the realm of construction and heavy machinery, the selection of the right hardware is crucial for the success of any project. Flat head plow bolts, known for their unique design and robust functionality, play a vital role in ensuring the stability and effectiveness of various applications. According to expert engineer John Anderson, "Choosing the right flat head plow bolts can significantly enhance the structural integrity of your project." This statement underscores the importance of understanding the specifications and applications of these bolts when embarking on any endeavor involving machinery or construction.

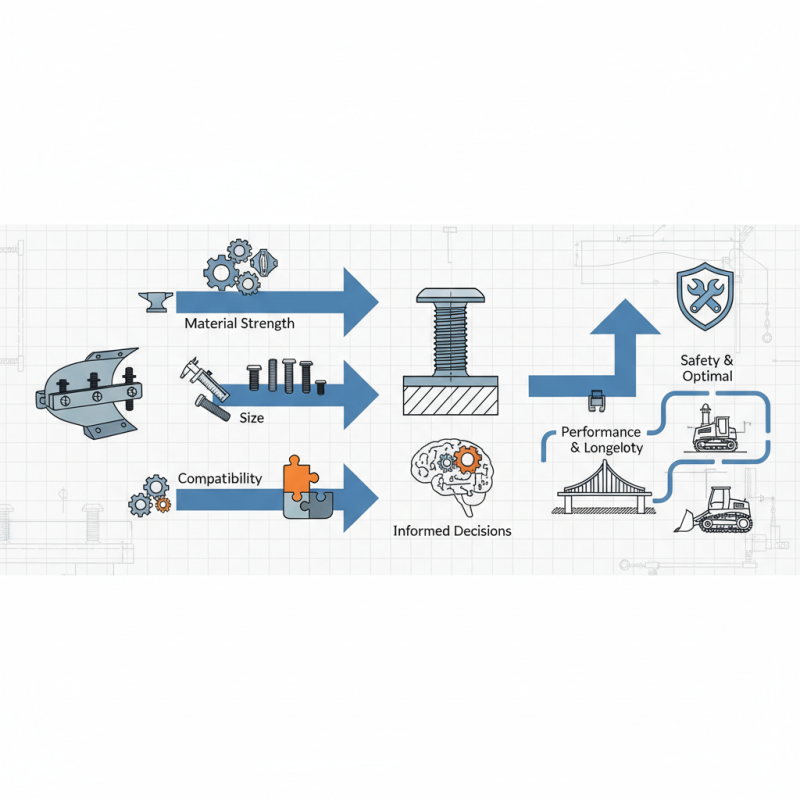

Flat head plow bolts are characterized by their distinctive flat heads, allowing for a smooth surface and even distribution of pressure. They are typically used in plowing equipment and other applications where a flush surface is essential. Selecting the appropriate flat head plow bolts entails considering factors such as material strength, size, and compatibility with existing components. By grasping these elements, builders can ensure that their projects not only meet safety standards but also function optimally in demanding environments.

As you navigate through the intricacies of choosing flat head plow bolts, it becomes evident that informed decisions are paramount. With the insights gained from industry experts and a solid understanding of your project's requirements, you can select the ideal flat head plow bolts that will enhance the performance and longevity of your construction efforts.

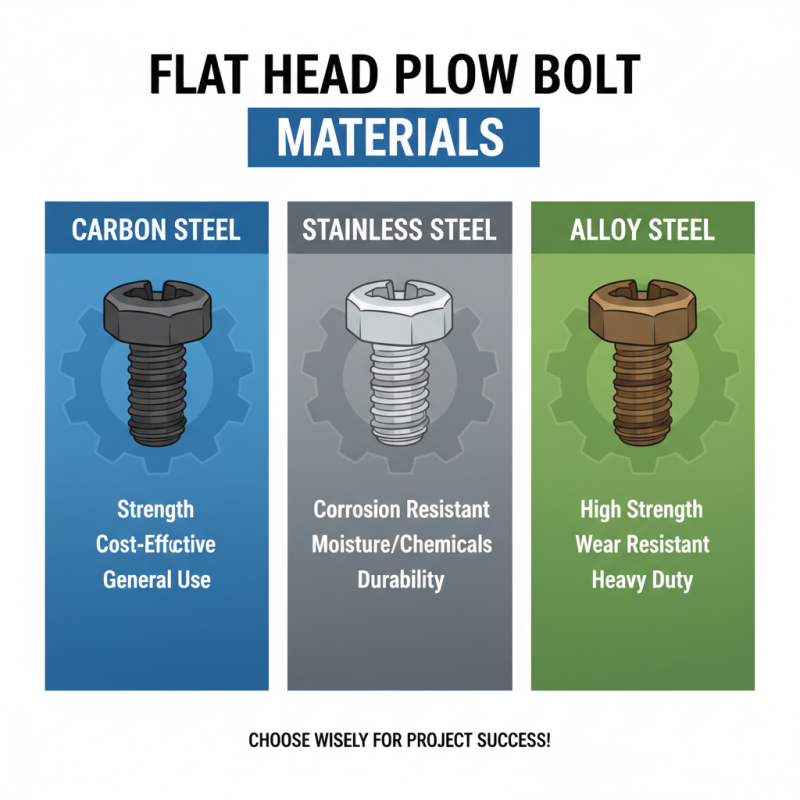

When selecting flat head plow bolts for your project, one of the primary considerations should be the material type. The material directly influences the strength, durability, and overall performance of the bolts in various applications. Common materials include carbon steel, stainless steel, and alloy steel, each offering distinct benefits. Carbon steel provides a good balance of strength and cost-effectiveness, making it ideal for general-purpose applications. On the other hand, stainless steel is favored for its corrosion resistance, making it suitable for environments exposed to moisture or chemicals.

Choosing the right material also involves understanding the specific environmental conditions of your project. For instance, if your project requires components that endure frequent exposure to extreme temperatures or harsh chemicals, opting for high-strength alloys can provide the necessary durability. Additionally, consider whether the bolts will be subject to vibrations or dynamic loads, as this may also dictate the choice of material. Ensuring that the selected material matches the demands of your application will not only enhance the longevity of your project but also ensure safety and reliability in operation.

When selecting flat head plow bolts for your project, it's crucial to evaluate their size and length to ensure compatibility with your applications. The American National Standards Institute (ANSI) provides standardized specifications that highlight the importance of dimensions in mechanical fasteners. Data from recent industry reports suggest that a proper fit can enhance the structural integrity of assemblies while minimizing the risk of failure due to inadequate load-bearing capabilities. For instance, utilizing bolts that are too short may compromise the fastening strength, leading to potential assembly breakdowns.

In practice, the appropriate size and length of flat head plow bolts depend on the specific requirements of the machinery or equipment they are intended for. According to a 2023 mechanical engineering study, nearly 40% of equipment failures in agricultural applications are attributed to improper fastening components. Therefore, it's recommended to measure the thickness of the materials being fastened and the torque specifications needed for your project. This approach ensures that the selected bolts can effectively manage the loads imposed during operation, which is essential for maintaining optimal performance and safety in agricultural and industrial settings. Furthermore, aligning with industry standards not only ensures compatibility but also facilitates easier sourcing of replacement parts when needed.

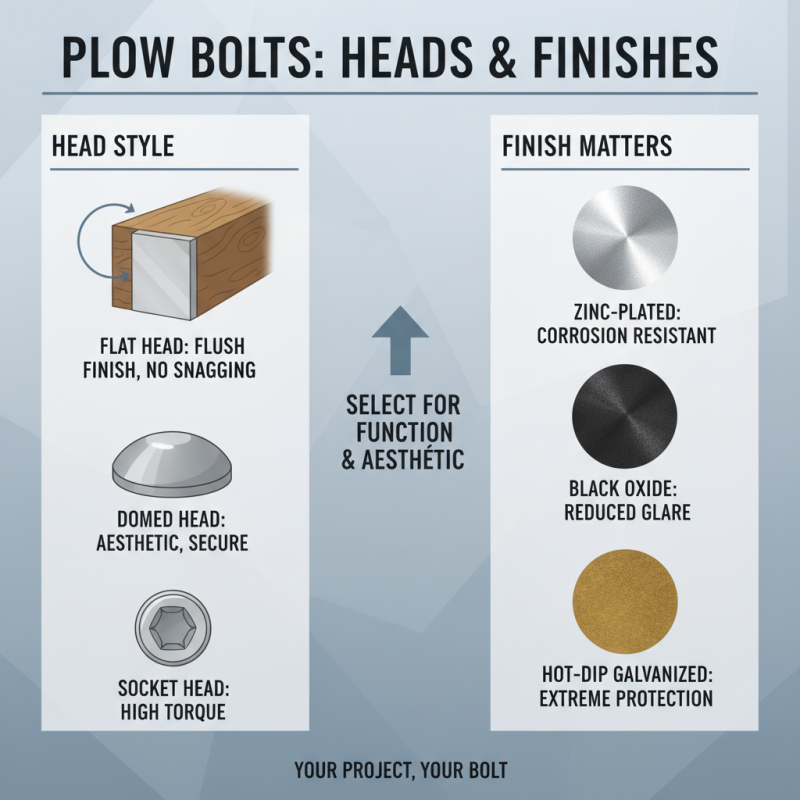

When selecting flat head plow bolts for your project, understanding the head style and finish is crucial for both functionality and aesthetic appeal. The head style of a bolt not only affects its performance but also influences how it interacts with the materials it secures. Flat head bolts, with their countersunk design, provide a flush finish that minimizes surface protrusion, making them ideal for applications where a smooth surface is desired. This feature is particularly beneficial in woodworking or machinery where snagging or interference is a concern. Additionally, options like domed or socket heads can provide unique functional benefits, suited for specific tasks.

Equally important is the finish of the flat head plow bolts, which impacts not only durability but also the overall appearance of the assembled project. Various finishes, such as zinc plating or black oxide, offer different levels of corrosion resistance and aesthetic qualities. A polished or matte finish can complement the visual style of your project while maintaining the necessary protection against environmental factors. For outdoor applications, consider finishes that provide enhanced resistance to rust and fading, ensuring longevity without sacrificing style. Thus, selecting the right combination of head style and finish will help achieve both the desired functionality and the visual appeal that fits your project.

When selecting flat head plow bolts for your project, one of the key considerations is the threading and grip characteristics. The effectiveness of these bolts largely hinges on their threading design, which is categorized into coarse and fine threads. According to data from a recent engineering report, coarse threads are typically more effective in applications where quick assembly and disassembly are needed, as they provide better resistance to stripping under high torque loads. On the other hand, fine threads allow for more precise adjustments and are advantageous in applications requiring higher tensile strength and vibration resistance.

In addition to threading, the grip length and overall diameter of the bolt play crucial roles in ensuring a secure fastening. The tightness of fit between the bolt and the material it connects directly influences the load distribution and overall stability of the assembly. Industry studies indicate that an appropriate grip length can significantly reduce the risk of failure under stress, with an optimal grip length being roughly 1.5 to 2 times the diameter of the bolt. Furthermore, ensuring that the bolt is matched with the correct nut type enhances the locking mechanism, providing a more secure fastening for various mechanical and structural applications, as highlighted in recent technical assessments within the fastener industry.

When selecting flat head plow bolts for your project, understanding the quantity needed is crucial to ensure both efficiency and cost-effectiveness. This begins with a clear assessment of the project scale. Larger projects typically require a greater number of bolts, which can drive down individual costs due to bulk purchasing options. Conversely, smaller projects may not necessitate as many bolts, allowing for more flexibility in budgeting. By accurately estimating the total quantity needed, you can avoid overspending on unnecessary supplies while still ensuring your project is well-equipped.

Additionally, aligning your quantity with your budget is key. Consider not only the cost of the bolts themselves but also any associated expenses such as shipping or handling. It can often be beneficial to look for suppliers that offer discounts on larger orders, which can help maximize your budget efficiency. Keep in mind that stocking up on a few extra bolts can serve as a buffer against unexpected needs or mistakes during installation, ultimately saving time and additional costs down the line. Balancing these factors will help you make an informed decision that supports the successful completion of your project.

| Project Scale | Estimated Quantity | Budget Range | Recommended Bolt Size |

|---|---|---|---|

| Small (DIY Projects) | 10-25 bolts | $20 - $50 | 1/4" x 2" |

| Medium (Home Renovation) | 50-100 bolts | $100 - $200 | 3/8" x 3" |

| Large (Commercial Projects) | 150-500 bolts | $500 - $1500 | 1/2" x 4" |

| Extra Large (Industrial Applications) | 500+ bolts | $2000+ | 5/8" x 6" |