Leave Your Message

In the ever-evolving landscape of construction and machinery, selecting the right components for your projects is crucial. Among these components, Flat Head Plow Bolts play an essential role in ensuring structural integrity and operational efficiency. According to industry expert John M. Richards, a renowned mechanical engineer and author of "Fasteners and Their Applications," "The choice of the right bolt can significantly influence the performance and durability of your equipment." This statement underscores the importance of understanding the various options available when it comes to Flat Head Plow Bolts.

When embarking on your next project, it is vital to recognize the factors that set apart quality Flat Head Plow Bolts from inferior alternatives. With a myriad of choices in material, size, and design, making an informed decision can be overwhelming. This guide aims to highlight the top ten considerations to keep in mind while selecting the best Flat Head Plow Bolts, ensuring that your projects not only meet safety standards but also enhance overall productivity. By leveraging expert insights and practical advice, we can demystify the selection process and empower you to make confident choices that will serve the longevity of your work.

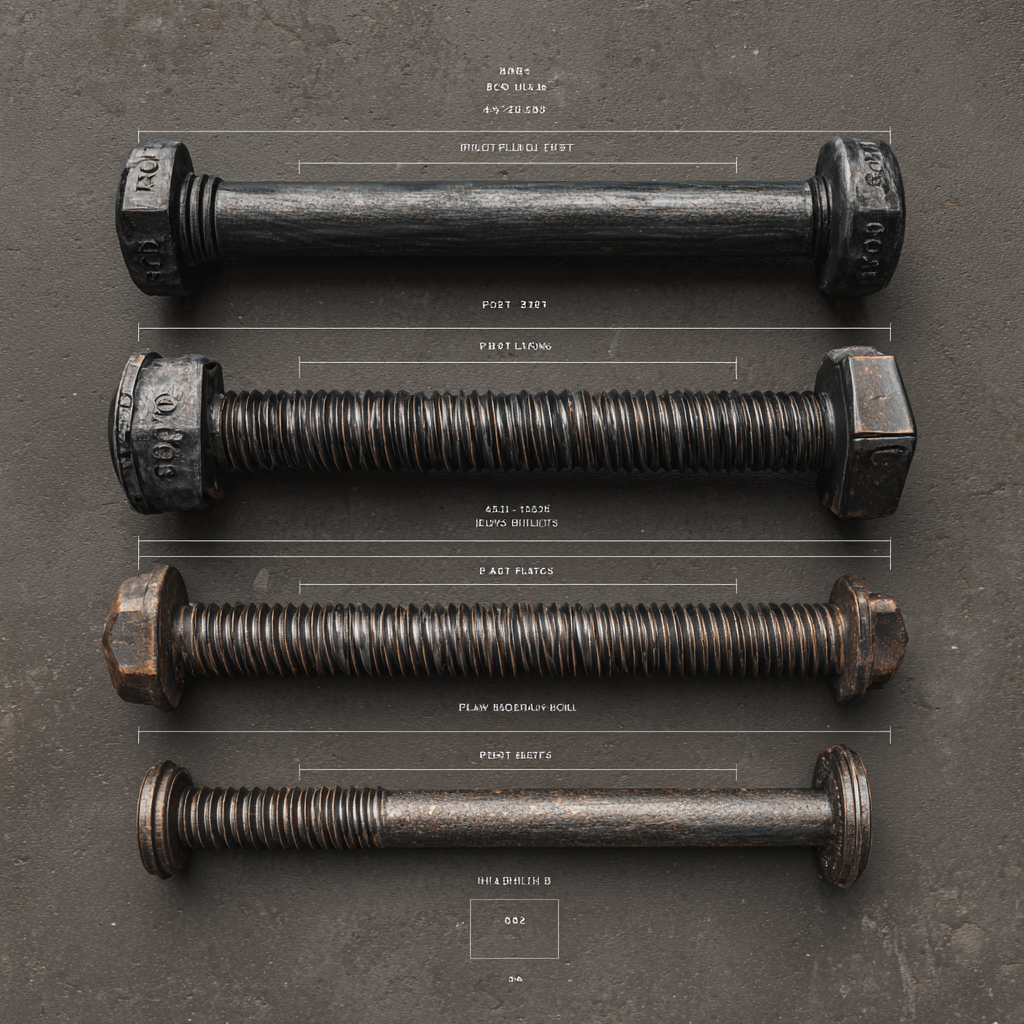

Flat head plow bolts are essential components in many construction and agricultural projects, thanks to their unique design that offers both functionality and durability. The flat head provides a larger bearing surface, which helps to distribute the load evenly and reduces the risk of deformation over time. This feature is particularly beneficial in applications where high torque is applied, as it allows for a more secure fit without risking damage to the material. Furthermore, the flat profile ensures that the bolt sits flush against surfaces, minimizing the chance of snagging or interference with other components.

In addition to their design advantages, flat head plow bolts are typically made from high-strength materials such as carbon steel or stainless steel, ensuring long-lasting performance even in demanding environments. Many come with additional protective coatings to enhance corrosion resistance, making them suitable for outdoor use or in corrosive settings. By understanding these key features and benefits, you can make informed decisions when selecting flat head plow bolts for your projects, ensuring optimal performance and reliability for your specific needs.

| Feature | Description | Benefits |

|---|---|---|

| Material | Steel, Stainless Steel, or Alloy | Durability and resistance to corrosion |

| Coating | Zinc-Plated, Black Oxide, or Plain | Enhanced protection against rust and wear |

| Head Type | Flat Head, Round Head | Cleaner finish, suitable for flush surfaces |

| Diameter | Varies (e.g., 1/4", 3/8", 1/2") | Compatibility with different applications |

| Length | Varies based on project needs | Adaptability to different material thicknesses |

| Thread Type | UNC, UNF | Precision fit and strength for secured fastening |

| Application | Construction, Machinery, Automotive | Versatility across various industries |

When selecting flat head plow bolts for your projects, understanding the different types of materials and coatings available is crucial for ensuring durability and performance. According to a report by the Industrial Fasteners Institute, the most commonly used materials for plow bolts include carbon steel, stainless steel, and alloy steel. Carbon steel is favored for general applications due to its excellent strength and affordability. However, for environments prone to corrosion, such as agricultural or marine settings, stainless steel provides superior resistance, making it a better choice despite its higher cost.

In addition to material considerations, the coating of plow bolts can significantly affect their lifespan and performance. A study published in the Journal of Coatings Technology highlights that zinc plating is a popular coating for flat head plow bolts, as it offers a good balance between corrosion resistance and cost-effectiveness. For projects needing enhanced durability, a powder coating might be more appropriate, offering thicker protection against environmental factors. By carefully considering both the material and coating options, you can choose the best flat head plow bolts tailored to the specific demands of your project.

When selecting flat head plow bolts for your projects, precise measurement is crucial to ensure compatibility with your materials and equipment. Start by identifying the diameter of the bolts you need. Use a caliper or a ruler for accurate measurement; the diameter is usually specified in inches or millimeters. It’s essential to consider the thickness of the material where the bolt will be fastened. Make sure to measure the thickness accurately to avoid purchasing bolts that are either too long or too short.

When selecting flat head plow bolts for your projects, precise measurement is crucial to ensure compatibility with your materials and equipment. Start by identifying the diameter of the bolts you need. Use a caliper or a ruler for accurate measurement; the diameter is usually specified in inches or millimeters. It’s essential to consider the thickness of the material where the bolt will be fastened. Make sure to measure the thickness accurately to avoid purchasing bolts that are either too long or too short.

Tips: Always account for the type of application when measuring; this can affect the required length of the bolt, as some applications may require additional thread engagement or considerations for washers and nut placement. Additionally, it’s wise to consult with project specifications or engineering drawings when selecting sizes.

Next, pay attention to the head style. Flat head plow bolts are designed to fit flush with the surface, providing a smooth finish. Measure the angle and depression of the head to ensure it fits properly in the intended socket. Remember, the correct fit not only enhances aesthetics but also prevents potential damage to equipment during operation.

When it comes to using flat head plow bolts, proper installation is crucial for ensuring the durability and effectiveness of your projects. One important tip to keep in mind is to always pre-drill the holes in the materials you are fastening. This reduces the risk of splintering or damaging the materials and allows for a smoother installation process. Additionally, ensure that the holes are appropriately sized to accommodate the diameter of the bolts.

Another key practice is to use a washer under the head of the plow bolt. This helps distribute the load more evenly across the surface, preventing the bolt from pulling through the material over time. Make sure to select a washer that matches the bolt size for optimal support. Finally, always tighten the bolts to the manufacturer’s recommended torque specifications to prevent loosening due to vibrations or stress during use. Following these best practices will help you achieve a secure and reliable assembly in your projects.

When selecting flat head plow bolts for your projects, cost considerations play a significant role in ensuring long-term performance and durability. According to a recent industry report from the American Fasteners Institute, investing in high-quality flat head plow bolts can reduce the total cost of ownership by up to 25% over their lifespan due to decreased replacement and maintenance costs. Cheaper alternatives may seem appealing, but they often lack the strength and resilience required for demanding applications, leading to potential failures and increased expenditures.

Tips: Always assess the material specifications when choosing bolts. Bolts made of carbon steel or alloy steel can provide enhanced strength and corrosion resistance, making them a better investment. Additionally, consider the finish; galvanized or coated bolts can significantly extend the life of your project, especially in harsh environments.

Understanding the nuances of pricing can further improve your cost-effectiveness. Industry studies suggest that while the upfront cost for premium fasteners may be higher, the associated savings in maintenance and replacements often justify the investment. As a general guideline, select bolts that meet recognized industry standards for your specific application to ensure you're not compromising on quality for cost.