Leave Your Message

When it comes to maintaining the aesthetic and functional integrity of your vehicle, selecting the right Wheel Center Cap Bolts is crucial. These seemingly minor components play a significant role in securing wheel center caps, which safeguard critical wheel components from dirt and debris. According to a recent industry report by the Automotive Fastener Institute, improperly fitted or low-quality bolts can lead to an increase in maintenance costs by up to 30%, impacting vehicle performance and safety.

Expert in automotive fasteners, Dr. John C. Thompson, emphasizes the importance of choosing quality materials and specifications when he states, "Investing in the right Wheel Center Cap Bolts can save vehicle owners both time and money while enhancing the overall appearance of their vehicles." Understanding the specifications and compatibility of wheel center cap bolts with your specific vehicle model is essential for optimal performance and longevity.

This guide aims to provide invaluable insights into selecting the right Wheel Center Cap Bolts to ensure a secure and stylish fit for your vehicle’s wheels.

Wheel center cap bolts play a crucial role in maintaining the overall integrity and functionality of your vehicle's wheels. These small yet essential components secure the wheel center caps in place, preventing them from loosening or falling off during driving. Without properly fitted bolts, the center caps can vibrate and cause damage, leading to costly repairs and potential safety hazards. Ensuring that these bolts are of high quality and properly tightened is vital for both the aesthetic appeal and performance of your wheels.

Moreover, selecting the right wheel center cap bolts is important for vehicle compatibility. Different makes and models have specific requirements regarding the size, material, and thread pattern of bolts. Using inappropriate bolts can result in poor fitting, which not only compromises the aesthetic aspect but also affects handling and safety. Therefore, understanding the specifications for your vehicle's wheel center caps ensures a secure and reliable fit, enhancing both the look and function of your wheels while giving you peace of mind on the road.

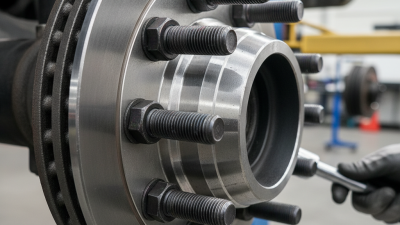

When selecting wheel center cap bolts for your vehicle, the most crucial step is identifying the right size and thread type. Start by measuring the diameter of the bolt holes on your wheel caps, using a caliper for precise measurement. Common sizes range from M6 to M12, so ensure you have the exact dimension, as using the wrong size can lead to improper fitment and potential damage to your wheels.

Next, determine the thread type. Most wheel cap bolts utilize metric threads, but some vehicles may require standard threads. Check the owner’s manual or consult with the manufacturer to pin down the exact thread pitch—this is typically indicated in millimeters (e.g., M8x1.25). Additionally, consider the material and finish of the bolts as these can affect durability and resistance to corrosion. By paying close attention to both size and thread type, you can ensure a secure and reliable fit for your wheel center caps.

When selecting wheel center cap bolts for your vehicle, one of the most critical aspects to consider is the material used in their construction. Durable and corrosion-resistant materials not only ensure longevity but also maintain the aesthetic appeal of your vehicle's wheels. Common materials for wheel bolts include stainless steel, aluminum, and chrome-plated finishes. Stainless steel is often preferred for its exceptional resistance to rust and wear, making it ideal for vehicles exposed to moisture or saline environments.

Another factor to evaluate is the specific environment in which your vehicle operates. If you drive in regions with heavy rainfall or road salt exposure, opting for bolts with high corrosion resistance is essential. Aluminum bolts are lightweight and provide decent corrosion resistance, but they may not be suitable for high-stress situations as they can weaken over time. On the other hand, chrome-plated bolts offer a shiny finish but can be prone to flaking if used extensively in harsh conditions. Ultimately, understanding the balance between material strength, weight, and corrosion resistance will guide you in making the best choice for your vehicle's wheel center cap bolts.

When selecting wheel center cap bolts for your vehicle, compatibility is paramount. Each vehicle model comes with specific requirements for bolt size, thread pitch, and material to ensure a secure fit. Always consult your owner’s manual or a trusted mechanic to ascertain the exact specifications needed for your wheels. Using bolts that don’t match your vehicle's specifications can lead to wheel vibration, loosening, or even damage to the wheel itself.

Tips to ensure you choose compatible bolts include measuring the existing bolts accurately — pay attention to diameter and length. Furthermore, check the thread pitch, which is crucial for proper installation. It’s also advisable to stick to bolts made of the same material as your original ones, such as steel or aluminum, to maintain durability and resist corrosion.

When purchasing new bolts, consider trying them alongside your center caps before finalizing your choice. Make sure they fit snugly without excessive force. Investing a little time to ensure compatibility now can save you from potential issues down the road, allowing you to drive securely and confidently.

When installing wheel center cap bolts, it is crucial to ensure a secure and effective fit. Begin by selecting the proper size and type of bolt for your specific vehicle model, as this will help prevent any potential damage to the wheel components. Before installation, clean the bolt holes and surrounding areas to remove any dirt or debris, which can interfere with the sealing and securing process. Using a thread locker can also enhance the bond, providing additional security against vibrations and movement over time.

During installation, use a torque wrench to apply the correct amount of force. It is essential to follow the manufacturer’s specifications for torque settings to avoid over-tightening, which can lead to stripping threads or cracking the caps. Start tightening the bolts in a crisscross pattern to distribute the pressure evenly across the cap, ensuring a stable fit.

After installation, it is advisable to periodically check the tightness of the bolts, especially after the first few drives, as they may shift slightly and require re-tightening. By following these tips, you can effectively secure wheel center cap bolts and enhance the longevity of your vehicle’s wheel assembly.