Leave Your Message

Choosing the right wheel bolts is an essential aspect of vehicle maintenance and safety that deserves careful consideration, especially as we step into 2025. Wheel bolts may seem like a small component in the grand scheme of a vehicle's performance, but their significance cannot be overstated. Properly selected and installed wheel bolts ensure that the wheels remain securely attached, which in turn affects the overall handling and safety of the vehicle.

As vehicles evolve with advanced technologies and designs, the specifications for wheel bolts also change. Factors such as material, length, diameter, and thread pitch play crucial roles in ensuring compatibility with different wheel types and vehicle models. In this guide, we will explore vital considerations for selecting the right wheel bolts, helping you make informed choices based on your vehicle's requirements and your driving habits. By understanding the importance of proper wheel bolt selection, you can enhance the safety and longevity of your vehicle's wheels, ensuring a smoother and more reliable driving experience.

When selecting wheel bolts for your vehicle in 2025, the choice of material plays a crucial role in performance and safety. The two primary materials for wheel bolts are steel and aluminum, each offering distinct advantages and disadvantages.

Steel bolts are renowned for their strength and durability, making them an ideal choice for heavier vehicles or those that endure rigorous driving conditions. Their resistance to deformation under stress ensures a secure fit, which is vital for maintaining wheel integrity.

On the other hand, aluminum bolts have gained popularity due to their lightweight nature, which can contribute to improved vehicle performance and fuel efficiency. The reduced weight helps in lowering the overall mass of the vehicle, facilitating quicker acceleration and enhanced handling. However, aluminum is generally softer than steel, which may raise concerns regarding their longevity, particularly under extreme conditions.

Therefore, it is essential for vehicle owners to weigh the specific requirements of their driving habits and vehicle type when deciding between steel and aluminum wheel bolts. The right choice can significantly impact both safety and driving experience in the upcoming year.

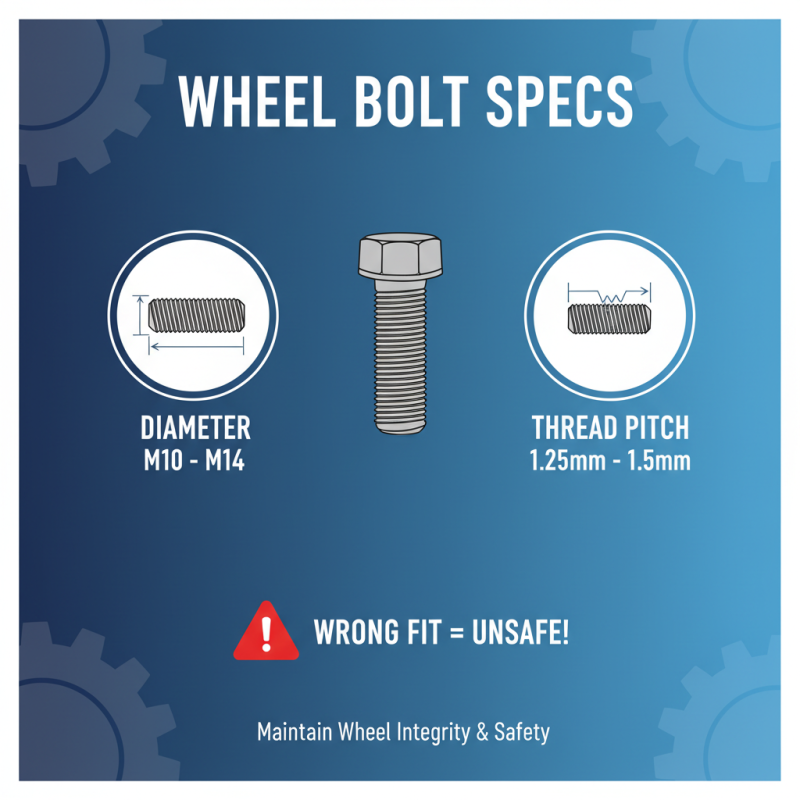

When selecting wheel bolts for your vehicle, understanding the specifications of diameter and thread pitch is crucial. The diameter refers to the width of the bolt shaft, while thread pitch indicates the distance between the threads. According to industry standards, a common metric bolt diameter for passenger vehicles ranges from M10 to M14, while the thread pitch typically varies between 1.25mm to 1.5mm for these sizes. Selecting bolts with the wrong specifications can lead to improper fitment, potentially compromising wheel integrity and safety.

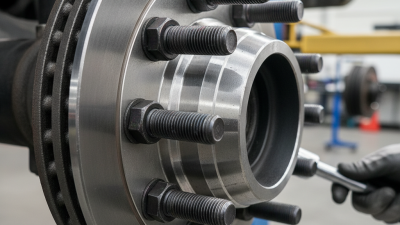

Research from the Automotive Engineering Society reveals that approximately 30% of vehicle accidents are attributed to wheel-related failures, often due to inadequate fastening. It is essential to refer to your vehicle's documentation or consult with manufacturers to obtain the correct size specifications. Additionally, torque specifications play a vital role in ensuring that the bolts are tightened correctly. Use tools such as torque wrenches to maintain the proper tension, as under-tightening or over-tightening can lead to disastrous consequences, including tire blowouts or wheel detachment while driving.

Proper torque specifications are crucial in ensuring the safety and performance of a vehicle. According to the Society of Automotive Engineers (SAE), nearly 80% of wheel-related failures are attributed to improper installation or inadequate torque. When wheel bolts are not tightened to the manufacturer's recommended specifications, it can lead to serious safety hazards, such as wheel detachment while driving, which poses significant risks not just to the driver but also to other road users. A study published in the Journal of Vehicle Safety emphasizes that consistent adherence to torque settings significantly reduces the likelihood of wheel-related incidents, underscoring the importance of proper tightening practices.

In 2025, as vehicle technology continues to evolve, so do the materials and specifications of wheel bolts. Advanced alloys and designs enhance durability, but they also necessitate precise torque application to maximize their performance. The National Highway Traffic Safety Administration (NHTSA) warns that neglecting to follow torque specifications can compromise the integrity of wheel assemblies, leading to uneven wear and costly damages. It is recommended that vehicle owners familiarize themselves with torque specifications outlined in their vehicle’s manual and employ tools such as torque wrenches to ensure accurate tightening. This attention to detail not only enhances safety but also prolongs the lifespan of various suspension components, ultimately contributing to a smoother and safer driving experience.

When selecting the right wheel bolts for your vehicle, understanding thread length is crucial for both fitment and overall performance. A study by the Automotive Engineering Society found that inappropriate thread length can lead to improper clamping force, which ultimately affects wheel stability and can increase the risk of wheel detachment during high-speed driving.

Thread lengths that are too short may not engage adequately with the wheel hub, while excessively long bolts can lead to interference with wheel components, potentially causing damage or compromising safety.

Moreover, the optimal thread length can vary significantly based on the type of vehicle and the wheels being used. According to the Society of Automotive Engineers, ensuring that the bolt length corresponds to the wheel application is vital. For instance, passenger vehicles typically require a bolt length between 25mm to 30mm, whereas larger SUVs and trucks may necessitate bolts ranging from 30mm to 45mm. A precise assessment of thread length not only enhances fitment ease but also ensures that the designed clamping forces are achieved, contributing to better handling and performance while driving.

When selecting wheel bolts for a vehicle in 2025, compliance with industry standards is paramount. These standards are designed not only to ensure the quality of the components used but also to maximize safety for all vehicle occupants. In 2025, manufacturers are expected to adhere strictly to updated guidelines that address material durability, load capacity, and corrosion resistance. This means that when choosing wheel bolts, it is essential to verify that they meet or exceed these specified standards to ensure reliable performance and longevity.

Moreover, the impact of safety regulations extends beyond the materials themselves. Proper installation and torque specifications must also comply with industry norms. Using wheel bolts that conform to current safety metrics helps prevent potential hazards related to wheel detachment during use. Vehicle owners should always check for certification marks or labels that indicate compliance with recognized safety protocols. By prioritizing these standards, drivers can protect themselves and their passengers while enhancing the overall performance of their vehicles.