Leave Your Message

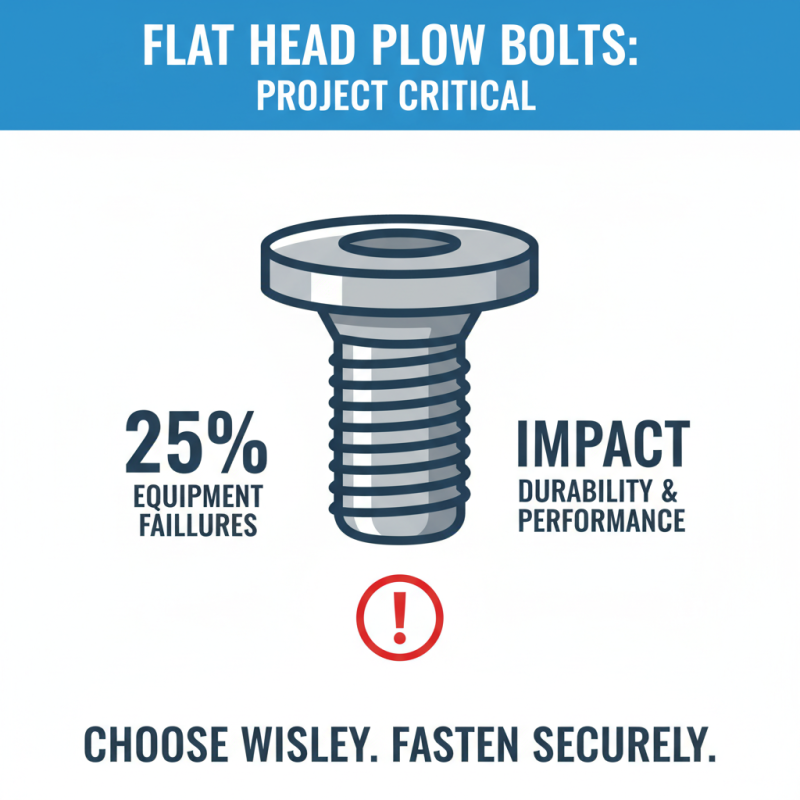

Choosing the right Flat Head Plow Bolts is crucial for various projects in construction and agriculture. These bolts significantly impact equipment durability and performance. According to industry reports, the wrong choice can lead to costly repairs and downtime. Approximately 80% of plow failures stem from using inadequate fasteners.

Flat Head Plow Bolts are designed for specific applications. They offer flat heads that enable a flush fit. This feature is vital in preventing damage during heavy use. However, selecting the wrong grade can cause issues. It is essential to be meticulous about materials and strength requirements.

In the fast-paced world of equipment repair, overlooking details can be detrimental. Many professionals admit to having faced problems due to improper bolt selection. Reflection on past projects can lead to better choices in the future. A thorough understanding of Flat Head Plow Bolts will ensure optimal performance and longevity in your work.

Flat head plow bolts are essential fasteners for various applications. They feature a unique design with a flat top that allows them to sit flush with the surface. This characteristic makes them ideal for use in areas where a smooth finish is necessary. They provide secure fastening in machinery and equipment, particularly in agricultural settings.

When choosing flat head plow bolts, consider the materials. Steel is common, but options vary. The right material impacts durability and resistance. Corrosion resistance is vital if the bolts face harsh conditions. Evaluate the length and diameter as well. These measurements ensure a proper fit for your project. However, selecting the wrong size can lead to complications.

It’s important to reflect on your specific needs. Not every project requires heavy-duty bolts. Sometimes, lighter options might suffice. Think about the application and environment carefully. Are you working indoors or outdoors? The conditions can influence your choice significantly. Misjudging the requirements can lead to frustration later. Always double-check your selection before proceeding.

Choosing the right flat head plow bolts is crucial for any project. The quality of these fasteners can significantly impact durability and performance. According to industry reports, nearly 25% of equipment failures can be traced back to the use of improper fasteners. This shocking statistic underlines the importance of selecting the right bolts.

One primary factor to consider is material. Flat head plow bolts typically come in steel, stainless steel, and alloy options. Steel offers great strength at a lower cost but may rust in certain conditions. Stainless steel, while more expensive, provides excellent corrosion resistance. For harsh environments, investing in alloy bolts could prevent potential breakdowns, as they withstand extreme conditions better than standard options.

Another key factor is the bolt’s dimensions. The diameter and length of a plow bolt can affect how well it fits into the application. The standard size may not always be suitable. Performing a thorough assessment of your project requirements helps avoid future headaches. Data suggests that improper sizing can lead to a 15% increase in operational failures, which is significant for any project timeline. Striking a balance between quality and cost while ensuring the proper fit will ultimately lead to better project outcomes.

When selecting flat head plow bolts, materials play a crucial role. Common options include carbon steel and stainless steel. Carbon steel is durable and cost-effective but may corrode over time. Stainless steel offers excellent corrosion resistance, making it suitable for outdoor or high-humidity environments. According to industry reports, nearly 70% of contractors recommend stainless steel for projects that face environmental challenges. This ensures longevity and reduces maintenance concerns.

Coatings can significantly enhance bolt performance. Galvanization is a popular choice, providing a protective zinc layer against rust. Research indicates that galvanized bolts last up to 50% longer in harsh conditions. Alternative coatings, like epoxy or powder coatings, also improve aesthetics and offer protection. However, they may not withstand mechanical stress as effectively. This is where careful consideration is needed.

Understanding project requirements is vital. Assess load-bearing needs, environmental factors, and budget constraints. Sometimes, choosing a lower-cost option can lead to higher long-term expenses. Balancing these aspects requires thoughtful planning. The right choice may not always be clear, and reevaluation is essential in maintaining project integrity.

Measuring flat head plow bolts correctly is crucial for a successful project. Incorrect measurements can lead to improper fittings and complicate the entire assembly process. Start by gathering essential tools—calipers or a measuring tape.

To measure the diameter, align the bolt against the calibrated tool. Make sure to measure from the widest points. Remember, even minor discrepancies can cause problems later. For the length, consider both the head and the shank. Ensuring accuracy in these dimensions is vital.

Take note of the flat head’s height as well. This dimension affects how the bolt fits within the groove. Double-check all measurements, and don't hesitate to remeasure if needed. A small mistake now can lead to large setbacks down the line. Consider creating a checklist to avoid missing any key measurements. It might seem excessive, but it helps in maintaining precision.

Flat head plow bolts are essential in various applications, especially in agriculture and construction. These bolts provide a flush surface, preventing snagging, which is crucial for machinery like plows and harrows. According to industry reports, over 70% of agricultural equipment relies on sturdy fastening solutions, highlighting their importance in enhancing efficiency and safety.

Specific applications include fastening plow blades to frames. The flat head design allows easier soil movement without obstruction. Surveys indicate that using the right bolts can reduce downtime by 30%. Additionally, in construction, they secure forms and templates, ensuring structural integrity. A report shows that projects with proper fastener selection experience fewer delays.

However, choosing the right flat head plow bolt isn’t always straightforward. Many overlook factors like material type and corrosion resistance. A study found that 40% of projects failed due to incorrect fastener choices. This highlights the need for better education on identifying suitable options. It's essential to reflect on requirements before making a selection, as improper choices can lead to costly repairs.