Leave Your Message

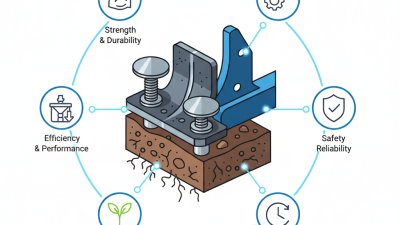

In the realm of construction and manufacturing, the choice of fasteners plays a critical role in ensuring the longevity and durability of structures. Among the various options available, "Galvanized Square Bolts" have emerged as a preferred solution for many professionals. According to a report published by the International Fastener Association, approximately 30% of all fasteners used in construction are galvanized due to their superior corrosion resistance, which is crucial in environments exposed to moisture or extreme temperatures. This statistic underscores the value that galvanized coatings bring to fasteners, significantly extending their lifespan and reducing maintenance costs.

Moreover, a study by the American Society of Civil Engineers highlights that the use of galvanized fasteners can increase the overall sustainability of a project. With structural integrity being a top priority, choosing galvanized square bolts not only enhances performance but also contributes to environmentally responsible construction practices. Their unique shape allows for optimal load distribution, ensuring that connections remain strong under varying conditions. Hence, as project managers and engineers seek reliable and efficient solutions, the growing preference for galvanized square bolts becomes increasingly clear, ensuring projects can withstand the challenges of time and nature.

Galvanized square bolts are increasingly recognized in construction and engineering for their superior durability and versatility. The use of hot-dip galvanization, which coats the steel with a thick layer of zinc, provides essential corrosion resistance, crucial for projects exposed to harsh environmental conditions. According to the American Galvanizers Association, galvanized steel can last up to 70 years or more without significant degradation, making it an ideal choice for infrastructure projects, bridges, and outdoor constructions.

One of the significant benefits of galvanized square bolts is their ability to endure extensive wear and tear. In a study conducted by the International Journal of Structural Engineering, it was noted that structures using galvanized fasteners showed a 40% increase in longevity compared to those utilizing non-galvanized counterparts. This durability translates not only into long-term savings but also minimizes the need for frequent maintenance and replacements, thereby streamlining project timelines and budgets.

Tips: When choosing galvanized square bolts for your project, consider the appropriate size and load-bearing capacity to ensure safety and reliability. Additionally, keep in mind that while the upfront cost may be higher than regular bolts, their longevity can lead to overall cost savings. Regularly inspect bolts during maintenance checks to catch any potential issues early, ensuring the integrity of your structures remains intact.

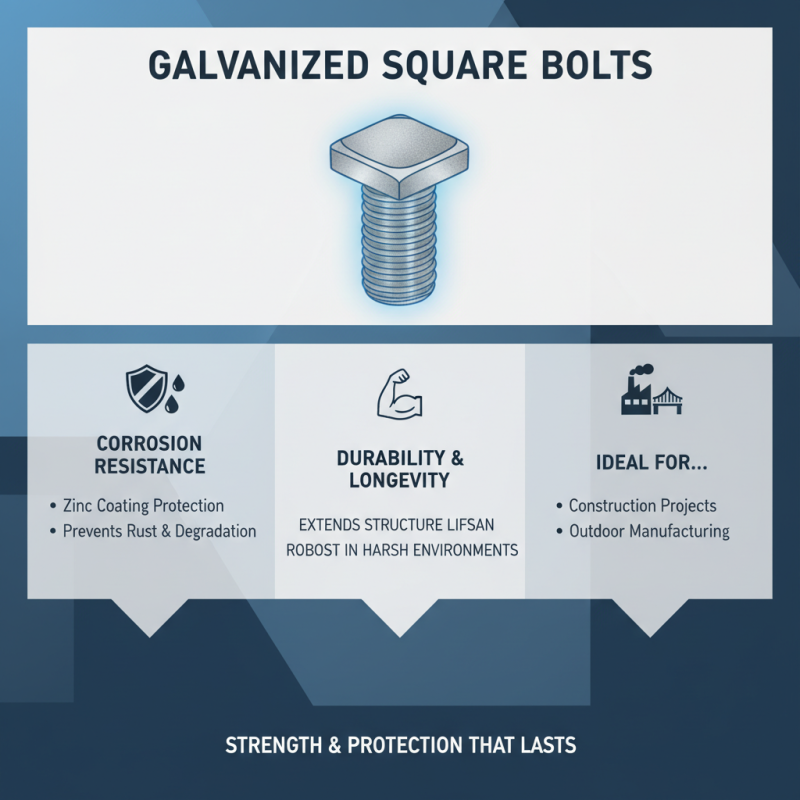

When considering materials for construction or manufacturing projects, the choice of fasteners can significantly impact the overall durability and longevity of the structure. Galvanized square bolts are renowned for their robust properties, primarily due to their galvanized coating, which provides excellent corrosion resistance. This protective layer helps to prevent rust and other forms of degradation that can compromise the integrity of metal components, especially in harsh environmental conditions.

Understanding the mechanics of how galvanization works is essential for making informed decisions. The process typically involves coating steel with a thin layer of zinc, which acts as a sacrificial barrier. This means that, in the event of any scratches or damage to the coating, the zinc will corrode first, protecting the underlying metal from exposure to moisture and corrosive elements. This inherent resilience makes galvanized square bolts a reliable choice for projects that may be subjected to moisture, chemicals, or fluctuating temperatures, ultimately leading to lower maintenance costs and extended service life.

When undertaking large projects, one of the paramount considerations is cost-effectiveness. Galvanized square bolts offer an excellent solution for budget-conscious builders and contractors. These bolts undergo a galvanization process that enhances their resistance to corrosion, making them a durable choice for various climates and conditions. By opting for galvanized square bolts, project managers can significantly reduce maintenance costs and extend the lifespan of structures, which ultimately leads to lower long-term expenses.

In addition to their durability, galvanized square bolts are usually competitively priced. The initial investment in galvanized materials can be offset by the savings on repairs and replacements that would arise from using less robust alternatives. This cost-effectiveness becomes even more evident in large-scale projects where the volume of fasteners required can lead to significant cumulative savings. Ultimately, choosing galvanized square bolts can provide both economical advantages and reliable performance, making them an ideal choice for large-scale applications where budget and longevity are critical factors.

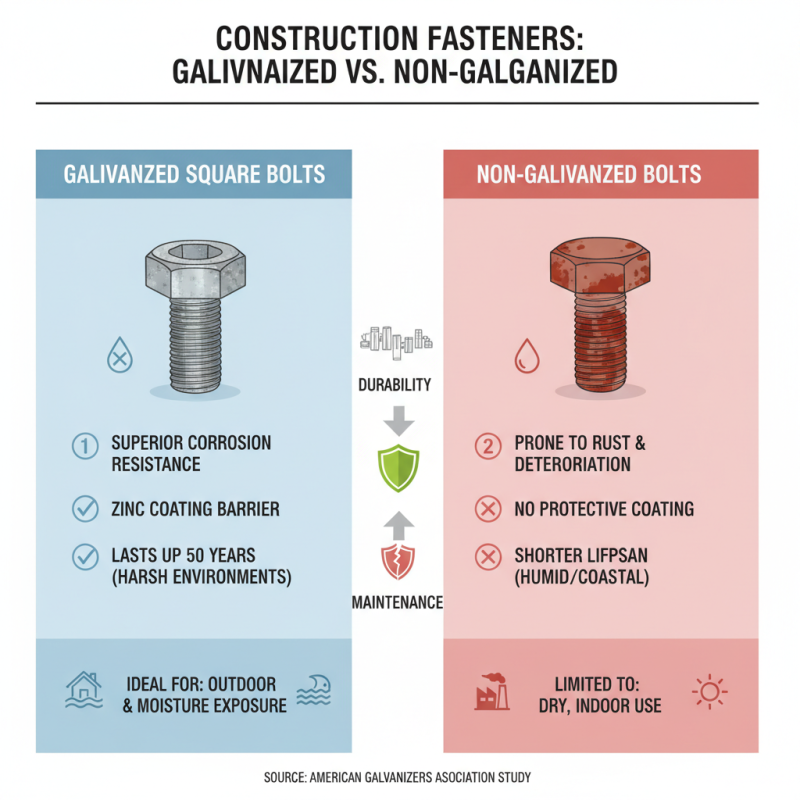

When selecting fasteners for construction projects, the decision between galvanized and non-galvanized bolts can significantly impact durability and performance. Galvanized square bolts, known for their superior resistance to corrosion, have a zinc coating that provides a barrier against environmental elements. According to a study by the American Galvanizers Association, galvanized steel can last up to 50 years in harsh environments, making it a preferred choice for outdoor applications and projects exposed to moisture. In contrast, non-galvanized fasteners may succumb to rust and deterioration much sooner, especially in humid or coastal regions.

When comparing performance, galvanized fasteners also show improved mechanical properties. A report by the Steel Stud Manufacturers Association highlights that galvanized fasteners maintain their strength and integrity under high-stress conditions, while non-galvanized options may weaken over time, leading to structural failures. Moreover, the added zinc layer enhances the bolt's load-bearing capabilities, making it crucial for heavy-duty applications.

Tip: When choosing the right fastener for your project, consider the environmental conditions it will face. If you anticipate exposure to moisture or corrosive elements, opting for galvanized bolts can save you time and maintenance costs in the long run. Additionally, ensure that the bolts you select meet the necessary specifications for your project to guarantee optimal performance.

When selecting galvanized square bolts for your projects, understanding the industry standards and certifications that govern these fasteners is essential. Galvanized fasteners undergo a protective coating process that enhances their corrosion resistance and longevity, particularly in harsh environments. Certifications such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) ensure that these bolts meet specific mechanical and durability criteria, making them a reliable choice for construction and engineering applications.

Moreover, industry standards dictate not only the quality and performance of galvanized square bolts but also their dimensions and material properties. Adhering to these standards ensures compatibility and reliability in various applications, from building infrastructure to manufacturing equipment.

Recognizing the importance of these certifications instills confidence in the use of galvanized fasteners, as they provide assurance that the products will perform effectively and maintain structural integrity over time.

Understanding these regulations can help project managers and engineers make informed decisions, ensuring that their selections meet both safety and performance benchmarks.